-

Posts

2584 -

Joined

-

Last visited

-

Days Won

114

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Bassboy3313

-

-

Congrats, Dan!

- straight6pwr and Rekpoint

-

2

2

-

4 hours ago, jc43089 said:

I'm working as an electrical contractor now and supplies are a big issue. Simple stuff like breaker panels, meter pedestals, breakers, etc. And if you can get it the prices have gone up by 50% just this year on many things. Construction is really busy right now so it is probably due to both supply issues and increased demand.

I work as a lighting and controls engineer for a lighting rep agency selling to distributors and contractors and you are 100% correct. Our lighting manufacturers had at least 2-3 price increases this year alone. Lead times for fixtures and control devices have sky rocketed too. We are still super busy tho which is good.

-

Sent my personalized plate request in the mail at 6:45am this morning! 🤞

-

5 hours ago, gilber33 said:

Looks good! I like how that one is flush mount and is out of the way when you're not using it.

Thanks. I had the concrete guys recess a pit in the floor for it. The arms still sit above the floor for easier swing out, so not fully flush. But definitely better than when I had it just siting on garage floor.

-

-

Part of me wishes I got a maxjax lift instead of my scissor lift, due to it being in the way of jobs that are directly under the car. But then the space savings around the car of the scissor lift is the plus side. Either way, not having to deal with Jack stands and such makes any style lift well worth it.

-

So I've been having a rougher idle on the touring the past few weeks. I installed BMW Scanner and INPA on my spare laptop and connected it up. Cleared all the adaptations and scanned it for codes. These are what I pulled

Error Code 106 - Control Vanos Mechanicall Outlet Blocked or Jammed

Error Code 8 - Air Flow Meter

Error Code 106 could if been a few different things, cam sensor, vanos seals, vanos solenoids, etc. I decided to start swapping parts off the Z3 coupe to diagnose the problem. Started with the exhaust side cam position sensor. Swapped the part, cleared adaptations and Error codes, fired it up. Luckily first try was a success! Cam sensor cleared the Error Code 106.

For Error Code 8, I was going to swap MAFs, but unfortunately the 2.8L Z3 coupe MAF is the same size as the B25 MAF, not the B30 MAF. Decided to just go ahead a buy a new MAF off FCP Euro while purchasing tue new cam sensor and oring. Hopefully this is it and daily driving commences.

After this, still gotta full up the AC system and good to go. 👍

-

-

15 hours ago, YoungCR said:

I like how the wagon still towers over the coupe

Touring makes it look so tiny and the touring isn't even big 😂

-

- patsbimmer1, m42b32 and Rekpoint

-

3

3

-

-

After more failed attempts at coding the B25 DME (kept having issues with connecting and finding the dme in the software), it was time to turn to plan b. Thanks to @m42b32 for having an extra MS43 DME and being able to flash it with everything I needed. Joe ended up putting the stock B30 tune, EWS delete and SAI delete on it and it worked like a charm.

After a couple startups to see how things were going, the engine started running extremely rough and wouldn't idle. @B C ended up stopping over with his computer. We checked fuel injectors, good. Checked coilpacks, good. Nothing was obvious from the outside, so we plugged the computer in to check error codes. After translating a few we narrowed it down to the DISA valve. Turns out the plug wasn't fully seated on the connector. Plugged it in and purred like a kitten. Sweet!

Torqued down axle nuts and crank bolt, bled the clutch a million different ways until it finally got all the air out, dropped it on the ZHP wheels and took it for a short "around the block" drive. All seems pretty good.

Time to throw the front end back on, hood, fill AC install airbox and start daily it. 👍

- P_Roloff, patsbimmer1, m42b32 and 3 others

-

6

6

-

The coupe club has grown! Looks great, man!

-

My shitty s10 pickup is registered in Jefferson and I keep/drive it in Brookfield/Milwaukee all the time. 🤷♂️

-

-

On 6/17/2021 at 8:42 AM, B C said:

Very nicely done! Im in for the detailing party

Deal!

-

Like it never happened...

Still have to seam seal and undercoat the underside, but I'm very happy with it. Shifts through all gears like it should.

I have to get a new black leather shift boot instead of the grey one I found at the u-pull. Also, once this whole project is wrapped up, this thing is getting a full interior detail for sure. Yikes!!!

- Rekpoint, B C and patsbimmer1

-

3

3

-

Well I'll call that a success. Ended up cutting the dash console piece in one spot to make room. This spot will allow everything to bolt back together and never be seen. This extra space allowed me to cut back the carpet inside shifter area.

I made a template of the inside hump piece and traced it on the car to prep for cutting.

I then proceeded to cut it out carefully with a dremel, not to hit any of the wiring or catch something on fire.

Fits great and shifting feels exactly as it should now! 👍

Now I just have to get some panelbond, seam sealer and rivets to attach it permanently and put all the interior back together.

- patsbimmer1, pynacl and m42b32

-

3

3

-

4 hours ago, YoungCR said:

Interesting. So did all the xi's have the raised tunnel then?

This is my assumption based on everything I've read, seen and experienced through this process...

All preface lift e46 xit's, regardless of auto or manual, had the raised tunnel since bmw based all chassis' off of being manual even if they became auto's on the assembly line.

Then, for some unknown reason, the facelift xit's that were manual got the raised tunnel and auto's got the flat tunnel due to shifter assembly.

Again this is just my speculation with what I've seen and experienced.

-

-

-

- patsbimmer1 and timmer

-

2

2

-

-

16" 5x120 Rial Wheels w/ Blizzaks

in Parts For Sale

Posted

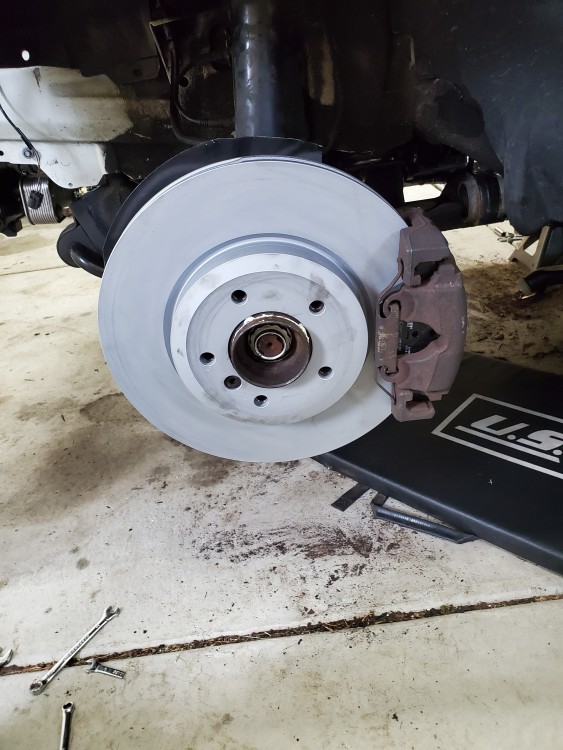

Selling a set of Rial 16" wheels 5x120 with Blizzaks 205/55R16 tires. Tread is still very good and wheels are super clean, No rash. Could use a cleaning tho. Had them on my 325 e46 touring before upgrading to 330 brakes. Maybe someone here can use them. Asking $500 elsewhere, but would entertain $400 for a wibimmers member.