-

Posts

258 -

Joined

-

Last visited

-

Days Won

26

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by AsparagusMike

-

-

Got a call from the shop this afternoon with some updates. They figured out what was causing the misfire issue and it was not the coils. After rewiring the original m50 coils back in they tested it out and the issue once again presented itself. They then pulled the injectors and ran them on a test station to find that supposedly a couple of them were staying stuck open. Threw a different set of injectors in it, did a pull and the issue appears to be gone. I do feel a bit frustrated as we went down this rabbit hole of diagnosing these coils, ecu and wiring just to find out the main cause of the issue was not related to any of that and was just a few bad injectors. I am glad to hear the issue was resolved though. They did ask if I wanted to wire the b58 coils back in but I told em to just leave the m50 ones in. They had it on the dyno this afternoon so if all goes well I should be hearing from them early next week!

-

On 1/15/2019 at 11:01 AM, straight6pwr said:

Diagram from The Book of E30 Ownership

On 1/15/2019 at 11:01 AM, straight6pwr said:before e30 turbo announcement:

perpetually non-running e30s ---------------------you-----running e30s

after e30 turbo announcement:

perpetually non-running e30s -------------you-------------running e30s

after e30 turbo installation:

perpetually non-running e30s -you-----------------------running e30s

This aged well

-

A little update on whats been going on so far

First off I wanna point out that the engine wasn't leaning out, it was having a random misfire condition that showed lean on the wide band since the 02 sensor was picking up the oxygen mixed in with the unburnt fuel. I realized I forgot to make that clear in my last post which I understand would cause some confusion as to why we were chasing a spark issue if the car was running lean lol.

Anyways, as per the original plan, they rewired the coils power and ground and rebuilt the sub harness to add a second relay. Although the car did slightly improve it did not completely correct the misfire issue. It did however correct the voltage loss we were seeing on the bore scope before so that was a plus. Next thing they tried was swapping in another set of known good b58 coils and a different set of plugs to eliminate a chance there was a bad coil even though they were new oe elders. When they were swapping them over the tech noticed that the coil boots didn't appear to be sliding all the way down to where they needed to be. Sure enough there was about a 10 mm gap between the spring inside the coil boot and the top of the plug! The swap brackets I was using weren't allowing the plug to fully seat. Thinking that they had discovered the main source of the issue, they ordered and installed some longer springs inside the coil boots to fill the gap. After all that they tested it out and the Issue still existed. Last thing they tried was pulling out the ms3 pnp and temporarily wiring in a ecu masters emu black to see if it was an ecu related issue. No change, misfire was still present.

At this point they had eliminated just about everything that could be causing this thing to essentially hit a wall when under heavier load (more then 20% throttle input). The engine runs great otherwise. Idles fine. You can drive it around under light throttle with no issue.

Only idea at this point was to remove the b58 coils and wiring and switch back to the m50 coils I originally had in there which I knew for sure worked fine. Took a trip down there last Tuesday and dropped off the pigtail harness and the old coils. Haven't heard anything yet but hoping to get an update by the end of this week.

-

Well, a little late on getting this update up but dyno day finally came around last Friday.

Went with Larry over at sound performance to get the tune dialed in. After arriving and getting everything unloaded we rolled the car in and started going through the pre-dyno checklist. Everything was looking great and they got the car up and running on pump 91. Not sure if I did mention this before but this time around I wanted to do a flex fuel tune so I had options versus just E85 before. Once up and running he dialed in the idle and they went ahead got it all strapped down to do some pulls.

First pull right off the bat he noticed the car lean out quite a bit right around 3500 rpms. Since everything else looked fine on the log we questioned if I was losing fuel pressure. Unfortunately I never did wire in a fuel pressure sensor so we could monitor that. So, we went ahead and spliced in a mechanical gauge to see if that was our issue. I should also note that when we went to do that he noticed I had my flex fuel sensor on my fuel supply line not return. Rookie me didn't realize that needed to be on the return so we swapped that around thinking that may have had some part in our issue.

Hopped back in and did another pull. Once again it leaned out and this time the car just quit. Watching the fuel pressure up to the cut out we noticed no drop in pressure, it held right where it needed to be. After realizing the fuel side was most likely not the issue, we questioned if it had something to do with the B58 coil packs I swapped in. Out came the bore scope and probed into the cylinder 6 ignition coil. Did another couple short pulls and they noticed that the voltage was falling off right after the coil dwell period when there was a call for spark. After further assessing the issue the guess was that the b58 coils required more voltage under load then the factory relay could offer and that was likely causing our lean out condition.

Unfortunately that meant nothing more could be done tell that issue was corrected. Correction for this issue most likely required wiring in a second larger relay to run just the coils.

The tough part was getting back in for tuning, they were booked out solid tell September. They then offered to do the work and said they then would be able to fit the car in to get tuned much sooner.

Left the shop their that afternoon with an empty trailer. I didn't get much of a time frame as to when they may get around to it as they had a decent amount of cars needing work but hoping to hear something before the beginning of August.

-

Well, got the break in oil dropped in and did a thorough look over of everything. I ended up using the old tune from the last setup for start up. Other then lower compression and different turbo this new setup wasn't much different from the old setup tuning wise. I figured it would probably run a little rich but still ok for idling and light throttle. Pulled the coils and plugs for ease of priming the motor and got a solid 15 psi of pressure shown on the gauge before re hooking up the fuel pump relay. Did another check over everything and then hopped in and started cranking...

Video was cut short as we noticed a coolant leak and shut it back off to correct that before letting it get up to temp. Once it was up to temp, I got the front valance re-installed and the car lowered on the ground. Being that the engine was running well and the afr's were looking good I wanted to get it out on the road and get some more load on the rings to break em in better. The tune obviously wasn't dialed in enough for this setup to see any kind of boost but some light to medium acceleration would be fine. Went down a few country roads near the shop and besides some trouble to stay idling at a few stops, the car ran really well!

Drove it around about 15 miles before returning to the shop and draining the oil right away and changing the filter.

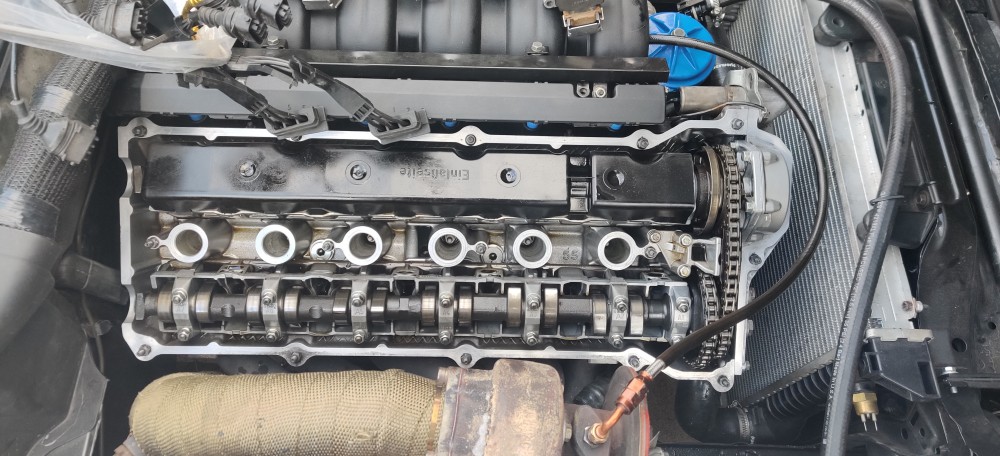

Also went ahead and popped the valve cover back off to re-torque the head studs. I did notice that the gasket had some coolant seeping out which was not ideal to see. I originally torqued the studs in three steps to 75 ft lbs as per arp's recommendations. I did some searching around and found that others had similar issues and followed ces motorsports recommendations of upping the final torque to 85 ft lbs to correct the issue. Re-torqued the head to 85 ft lbs and also checked the torque on all the cam caps before re-installing the valve cover.

So not to much left besides wrapping the wires up and getting things buttoned up. Got my tuning date scheduled but unfortunately that's not gonna be tell June 30th. Wish it could have been sooner but by the sounds of it everyone is booked out atleast a month for dyno tuning. Gives me plenty of extra time to really go through things so it can be fully ready to go.

- KaiserRolls, Boris3, SteelBlue and 3 others

-

6

6

-

On 5/4/2023 at 2:04 PM, GunMetalGrey said:

Watch that IAT for heat soak as it can do some weird stuff. I had it up so far toward the intercooler so the headlight cover plate would block off engine bay heat from the sensor as much as possible.

I've seen some guys rethread the port for the factory IAT to run the gm sensor and not have any heat soak problems so hopefully with the sensor located that far away I should be ok.

-

Been having a hard time getting on here to post updates so this one is overdue by about two weeks lol.

The car still had a full tank of E85 in it so right away I disconnected the feed line on the fuel filter, jumped the relay and put the hose in a gas can to pump out all the old fuel. Once I had about 95% pumped out I pulled the fuel pump assembly out and took a peak inside. Now I did pour some stabil 360 in the tank before storing the car away so I was hoping that would atleast keep the fuel from absorbing a bunch of moisture and rusting out the tank. Sure enough the tank was in perfect shape so that was great to see. Old fuel had a sour smell to it though so definitely wasn't about to dump it back in.

As for the fuel pump, it was time for something with a little more flow. The walbro 255 I had in there is suppose to be good for around 450 hp and being that I have plans to exceed that now I switched over and went with a DW300. With about 100 lph more then the 255 it should fit my power goals perfectly. I didn't want to go too over sized with the pump as I was sticking with running the stock FPR. Deatschwerks and walbro share the same pigtail so switching over the pumps was actually quite simple.

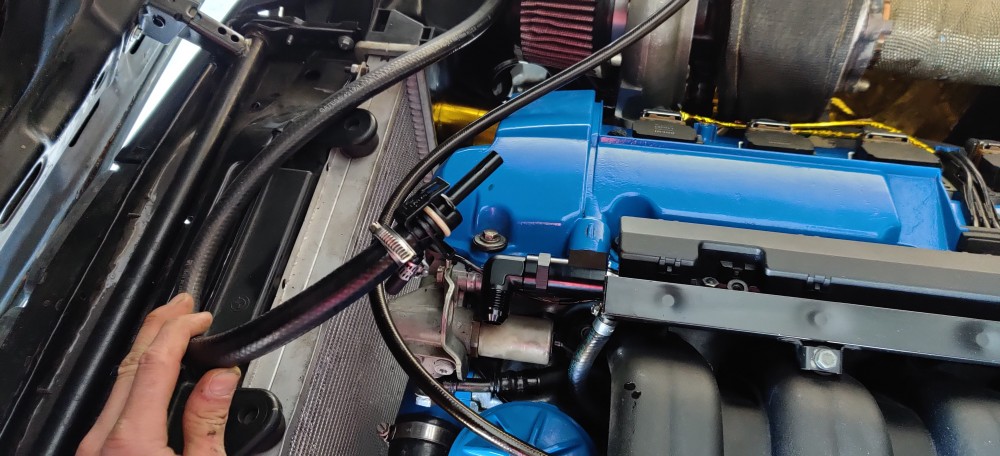

Ordered a relay kit as well to go with the larger pump. Factory wiring won't cut it no more.

New power ran directly to the battery with a 40 amp inline fuse. Ran the ground to the same grounding point that the battery uses.

Wire wrapped and heat shrank everything to clean things up.

Completely rewired the pump connector to work with the new relay. The brown wire heat shrank off is the old small ground for the pump.

Ran a new ground for the pump circuit to the existing ground point underneath the back seat rest.

Ran all the wires through the grommeted hole for the OE harness and then snuck them back over the top of the tank to keep things clean and avoid having to run wires under the pump access panel cover.

After the wiring was complete I took a multimeter and confirmed I had power at the plug.

On to more wiring fun! On the old setup I ran a speed density setup using the OEM IAT sensor. The factory sensor doesn't actually do very well for that and it is recommended to run a seperate IAT sensor (GM one is most common) on the charge pipe near the throttle body to measure temps better. Well the bung for the sensor was already welded in and the sensor actually already existed on the charge pipe installed by the previous owner of the kit. Thanks @GunMetalGrey. All that was needed now was to wire it in. Ordered a pigtail for the sensor and ran out to the junk yard and cut off a male connector that would plug into the factory IAT plug under the manifold. added some extra wire in for length so I could run it along with the main loom going down to the front valance.

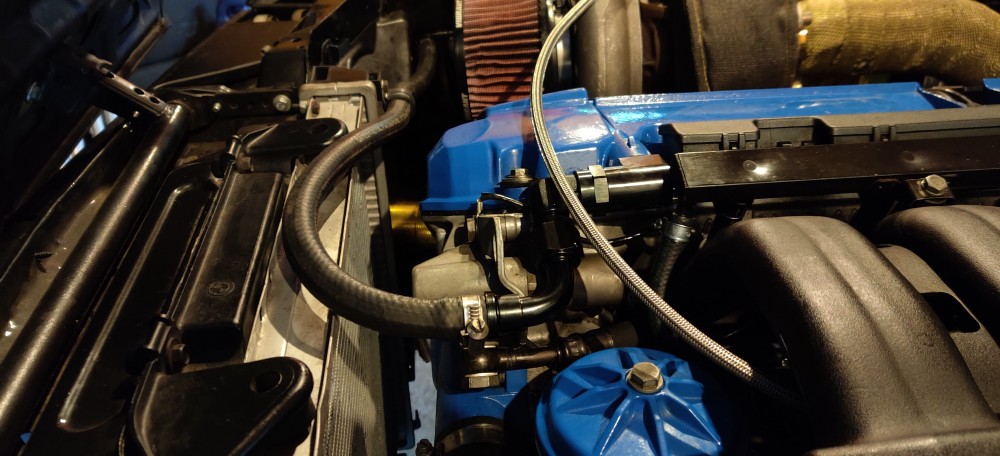

With that complete it was on to getting the catch can mounted up and plumbed. The can that came with the SLG kit is from vibrant. The bracket that comes mounted on it wasn't enough to mount it in the location I wanted it in. In order to do this I had my buddy cut and bend me up a piece of 1/8 inch stainless at work. Only thing from there was to mock it up and drill in the holes for the hardware.

Once the can was mounted up I plumbed in the AN lines. The vibrant catch can is quite large and with the -10 AN 90's tightened down on top of the catch can it is just barely gonna clear under the hood. The location was also nice for draining the can as I can get access to the drain plug pretty easy from underneath through the hole where the old ac dryer was located.

The old charge pipe running from the compressor housing to the silicone 90 on the intercooler was too short for the new setup. I got a new piece of aluminum tubing and cut it to the required length. Before installing, I roughed it up and shot it with a coat of a black semi gloss paint.

Totally forgot to get pics of it but I also got new vaccum lines installed for the wastegate housing as well. tied them in to the EBC which I relocated over to the right above the horn on the passenger side.

Radiator installed with coolant air lifted in. Exhaust installed.

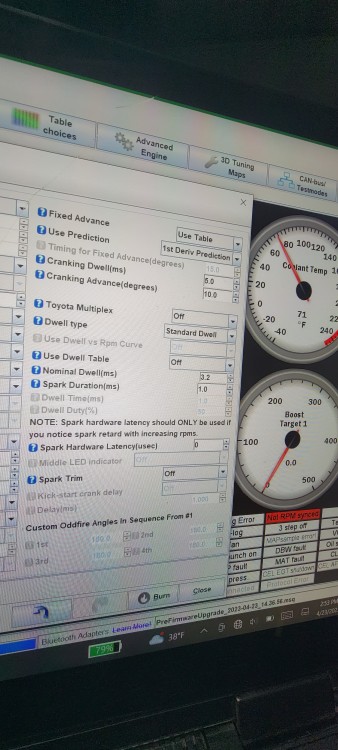

I pulled up tunerstudio and got my dwell timing adjusted for the b58 coils. There will most likely be some fine tuning required with those once on the dyno.

-

On 4/17/2023 at 9:51 AM, KaiserRolls said:

nice progress!

Rally road has something similar to that I had considered getting. I decided against it though after seeing the amount of success guys were having with just epoxying in a new oem one. I personally haven't found anybody mention anything about the epoxied in oem ones failing.

-

Well I reached the point where I figured it was time to roll the car into the shop. As any car that's been sitting in storage for a year it was quite dusty/dirty so I gave it a good spray down with the pressure washer before rolling it in.

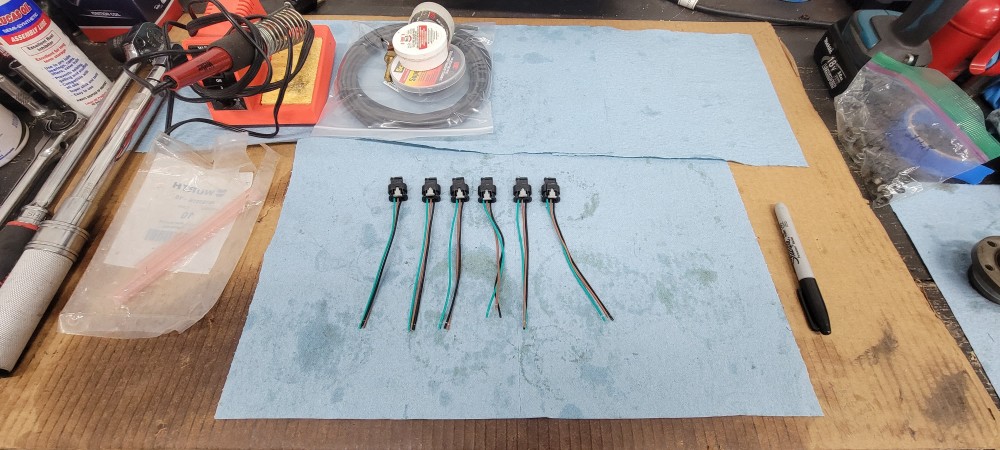

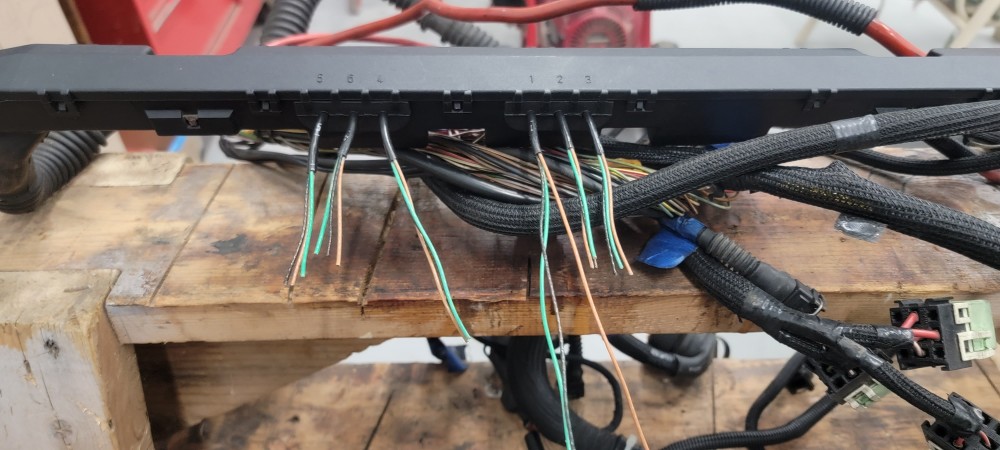

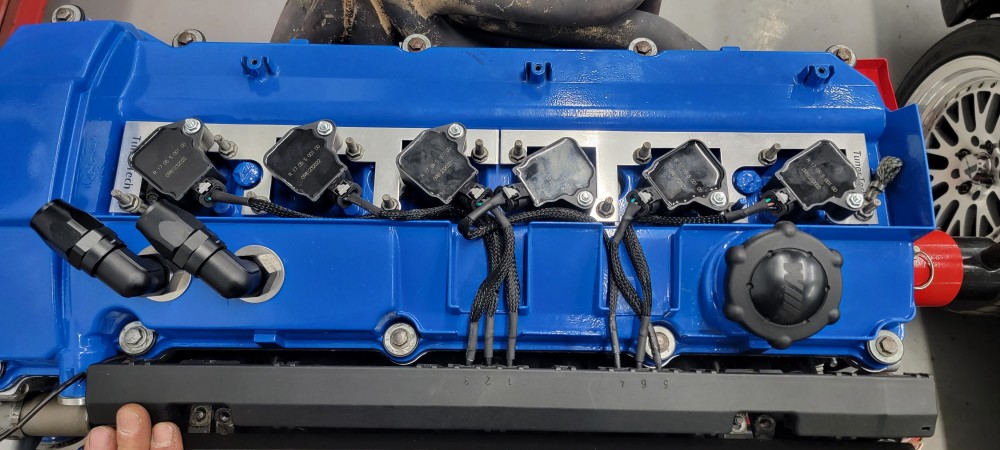

I dug into the re wiring required for the new coils. The pigtails sent with the swap brackets come with matching colored wires with the old connectors for the original coils so splicing them in was pretty straight forward.

Before cutting the old pigtails off I got that part of the harness laid out on the valve cover to see what I would need for lengths.

New pigtails soldered and heat shrank on

Ordered some 1/4 inch wire wrap with an assortment of shrink tube to clean everything up.

Only thing left is to adjust the dwell timing for the new coils in tuner-studio.

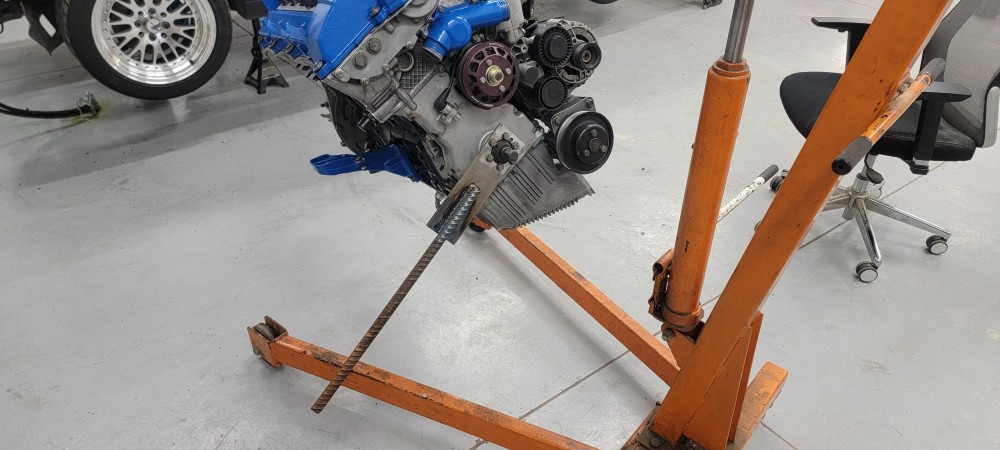

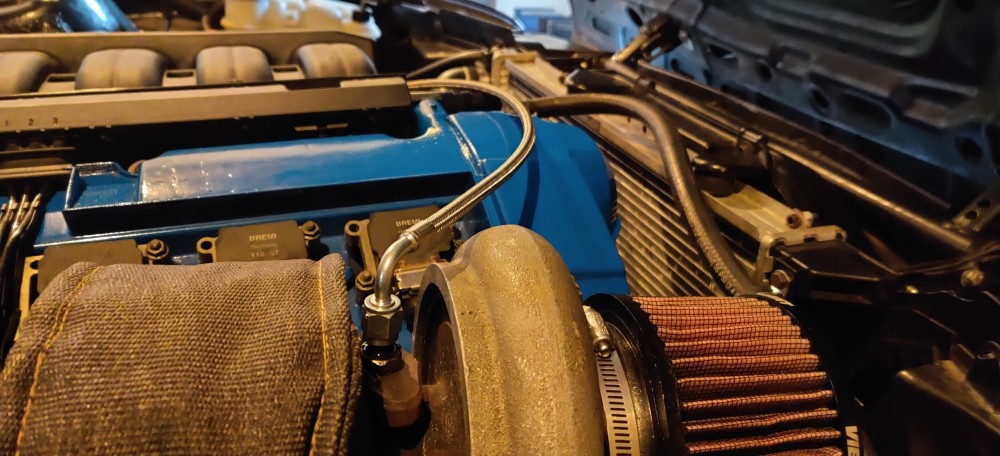

On to the next big task. So I decided it was time to move on from the holset and get something that would give me a bit more flow and better response. After spending a lot of time researching options and what would fit my setup best I landed on going with a PSR5855G from pulsar. It is essentially a clone of a Garrett G30-770. Now typically for this motor, this size turbo would be a bit on the small side but being that I don't plan to surpass 500 whp with this car I figured it would be perfect. I also had them do the t51r mod to the compressor housing right away. Looking forward to the added turbo sounds that will bring.

Next thing was to address another issue I was having on my old setup. Boost creep. Although these rapidspool manifolds fit pretty nice and make for a clean look in the engine bay, their design with the wastegate location was sub par. On the original setup I wasn't seeing it to bad, maybe 2 or 3 psi of creep at the worst but that was on low boost (8 psi). I feared with the new setup and plans of turning it up quite a bit more that it would get worse. Instead of spending more money on a different manifold I chose to reuse this manifold and run the wastegate right of the turbine housing as there is no better location for boost control.

(pic of the old setup and waste gate location)

So without further a do I had my buddy swing by with his much better tig welding skills and lend me a hand. Started on getting the down pipe adapted to the v band flange for the new turbine housing. Used one of the old cylinder heads I had laying around as a spot for supporting the manifold.

Waste gate pipe was cut back to the flange and capped off.

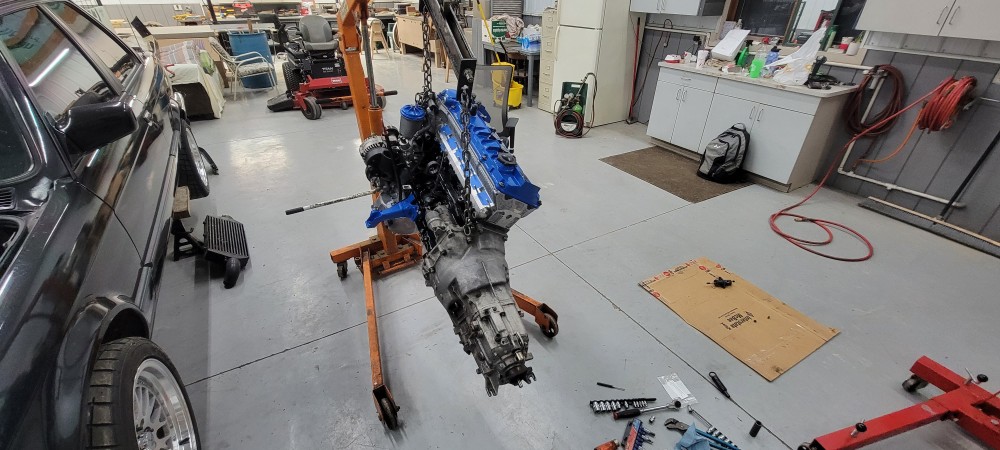

While he was working on that I switched over and worked on getting the freshly cleaned flywheel, clutch and trans installed.

Before I dropped the engine in the car I wanted to get the Jesus bolt torqued down. Found some scrap steel laying around that I was able to drill out to fit the harmonic balancer hub. With my buddy there welding on the manifold I had him quick weld it to some rebar for a handle and voila! We did end up sliding a cheater bar over the rebar to add extra leverage. For a quick thrown together tool it worked awesome for holding the hub to get to that 300 ft lbs.

With that in we got the manifold bolted up and figured out our new placement of the wastegate.

Cast iron drills much easier then I expected.

Although it drills easy, it is not so easy to weld. In order to avoid cracking the housing from the stress of the weld we first needed to heat up the entire housing with an acetylene torch to roughly 600 degrees.

After the welding was complete we wrapped the housing in a turbo blanket as an insulating barrier and monitored it with a temp gun to make sure it was cooling down slowly as letting it cool down too quick can also potentially cause stress cracks.

It was now time to pipe the waste gate. I personally really liked the much more mellow sound of the wastegate recirc'd back into the exhaust pipe for a street car vs just dumping it out the bottom somewhere. Luckily enough we were able to reuse most of the old wastegate pipe to route it back into the exhaust. Overall, I was pretty happy with the results and look forward to many boost creep free pulls in the future!

I also went ahead and had a elbow welded on to the compressor housing. My original plan was to run a silicone elbow there but with the smaller frame on this turbo, the elbow was touching the manifold and I feared it would melt it.

To keep engine bay temps down I got a new turbo blanket that better fits this housing and drilled a 2 inch hole in it to accommodate for the wastegate flange. Rest of the down pipe I wrapped with some heat wrap.

After wrapping this up I got all my an lines made up for the oil drain and cooling lines and installed them right away. Being that this turbo was ball bearing it meant I now had to run water to keep it cool. Ran the water inlet off the third port on the cylinder head next to the Coolant temp sensor. I chose to run the water outlet down into the block drain port.

Moved on to the intake side of things. Got the harness back into the car and hooked all up. As for the intake manifold I chose to use some plastic epoxy on the IAC port underneath so I didn't have to worry about that causing a leak.

Manifold is in and everything hooked up underneath. Also got the shifter linkage, driveshaft reinstalled and clutch pedal bled.

Fuel stuff showing up early this week. Lots of other little things to run and tighty up but the to do list is getting shorter!

- KaiserRolls and timmer

-

2

2

-

I have a set of 17 lb green tops and a set of 21.5 lb pink tops I'd sell

-

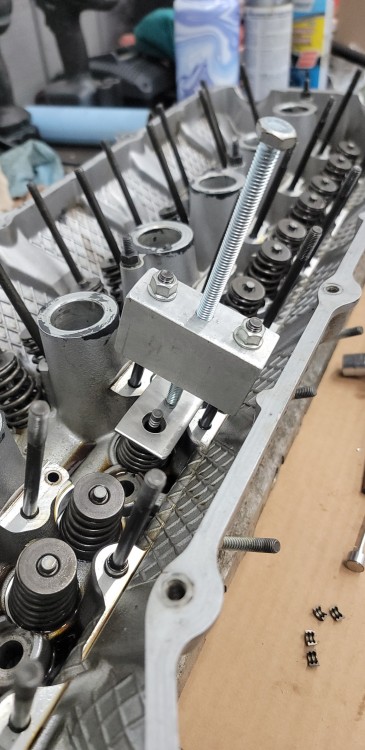

So as far the head I decided on leaving it fairly stock. As for right now I don't have plans of revving past 7k so it should be safe just running the stock valve train. The head I'm using was originally from a M50 vanos. The only difference between the head from a s52 and a M50 non vanos were the springs and retainers. I kept the springs matched with the cams I was running which was from the s52 so I needed to swap those over. I went ahead and installed all new valve stem seals at the same time.

Made myself a little tool for spring removal and installation. Not quite as nice as some of the ones you can buy out there but it did the job well.

Once that was complete I began reinstalling the intake and exhaust studs. For the exhaust side I reused the N54 studs from the previous motor for ease of installation. After inspecting all the holes I noticed one of them was missing half the threads in it, wonderful. So out came the Heli-coil kit.

Springs and new valve stem seals were in. Studs were all installed. Time to go on the motor.

For the head gasket I went with a stock thickness 87 mm Athena cut ring headgasket. I tapped in some new dowels and then test fitted the gasket first to make sure everything cleared and all the cut rings fitted properly.

Everything checked out good on the HG so before installing the head I popped it back off and ran a small bead of the right stuff gasket maker around the entire timing cover area. Most say it is only necessary to dab a little where the cover meets with the block but I feared since there was only M6 bolts compressing the head down in this area there was still a chance it could possibly still leak. I should also note that before installing the head I made sure all the pistons were all shifted to as close to the center of the bore as I could to avoid any valves coming into contact when the cams are installed.

Once the head was on I threaded in the rest of the arp studs using the moly lube provided and torqued them in three equal steps to 75 ft lbs.

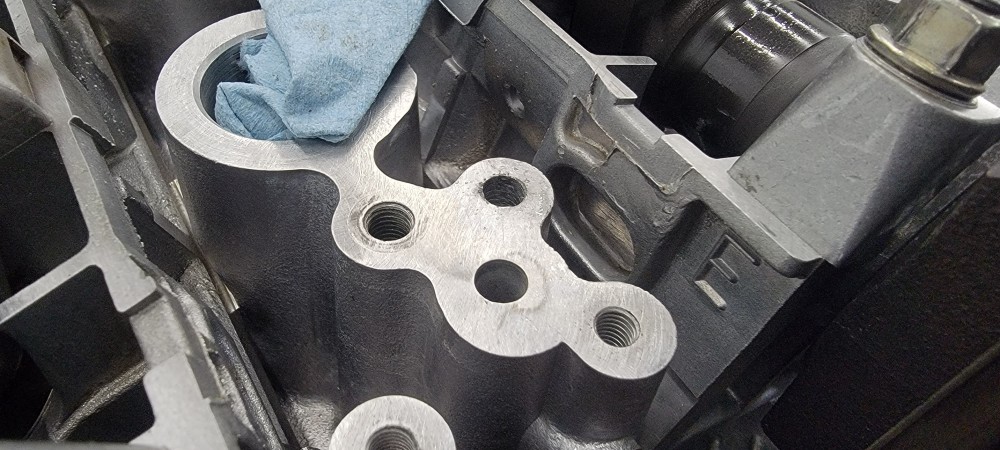

Trays and lifters were about ready to go in and then I noticed this in some of the bores on the exhaust tray

.

.

Some light scoring in these areas is typically normal but this was far beyond that which pretty much made them scrap metal now. Unfortunately the cam trays that I got with the M52 were different. One of them was for a M52 but the other was from a M50 non vanos head so that wasn't gonna work out either. Thankfully after some research I found that M52 and S52's actually use identical cam trays so I took a trip out to the local junk yard and luckily found an untouched M52 from a 98 528i with trays and caps that ended up being in great shape!

Since they were pretty heavily varnished I dropped them off at a local machine shop to run through a hot tank.

With those back and cleaned up I went through my two sets of lifters from the M52 and S52. The lifters from the S52 worked well for me in the last motor but they were also pretty scored up similar to the cam trays they were in and I was unsure about the ones from the M52 and how many miles were on them. So, instead of trying to clean those up and risking some of them still causing issues I resorted to just purchasing all new ones.

Sprayed all the new lifters down with some break cleaner and compressed air to remove the protective oil that they came covered in.

Before Sliding them in to the trays I dunked each lifter in some break in oil and compressed the inner piston a few times with my fingers tell the piston felt a little softer to compress. This was done to prime them with a little oil so they weren't dry on first start. After rubbing a little assembly oil in each bore of the trays I popped them all in.

I didn't snap any pics of the next part but the install of the trays and cams went smoothly. I dropped some assembly lube on all of the lifter tops as well as on the cam caps and bearing locations on the trays.

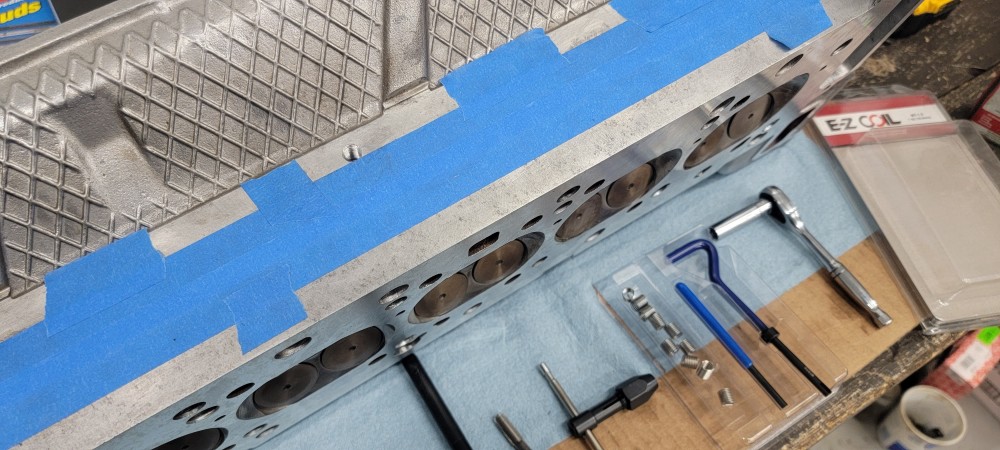

I then began installing all the upper timing components. When I was torquing down the four bolts that held the upper timing chain guide into place I was finishing up torquing down the last bolt on the back side to 10 NM when I felt that wonderful feeling of it come back lose again when I was just about torqued. Backed the bolt back out of the hole with broken pieces of threads attached to it. Out came the Heli-coil kit, again.

Covered and taped off all areas of the motor leaving only the hole exposed. While drilling and tapping the hole I had help with holding a vacuum right next to the hole to suck up any metal shavings.

New insert was installed and I got back to installing the timing components. This time everything was torqued down to the proper spec with no issue.

When installing the front cam sprockets a new upper timing chain was used. With everything timed correctly I got the vanos unit installed with a fresh oem gasket. Once that was all completed and all bolts were torqued down to spec I spun the motor around 720 degrees to make sure everything spun smoothly and nothing was interfering with each other.

Onto installing the valve cover and getting this thing closed up.

After the timing was complete I did start installing a lot of the outer parts and accessories as well.

Two things I added from the old setup included an upgrade to my crankcase breathing setup. The single oem port I was using on the old setup I felt was just not gonna be adequate enough so I purchased the catch can kit offered by SLG. The kit is pretty slick and comes with all the drill bits and taps needed for modifying the cover and plugging the factory hole as well as all the necessary AN fittings to install for the new catch can lines.

The other addition was the ignition coils. On the old setup I ran the original 20 year old obd1 coil packs. For the most part they worked just fine but they started showing their age when during an auto-x event they got heat soaked and caused the engine to misfire. Of course I didn't wanna run into that issue again so I either had to get a new set of oem ones or try something else. New set of coils would set me back close to $600 so I looked around to see what else was out there. Well sure enough I noticed quite a few other boosted e36 guys running coils out of a b58. I then came across a company called Tunertech that actually designed a full swap kit with custom brackets to fit the coils in the e36 valve covers and the necessary pigtails to splice into the harness to run em. The main advantages of running these coils were that they produce stronger spark energy over stock, allow you to run a looser spark plug gap resulting in smoother idle and the cost of the coils come in at around half the cost of the stock ones. Because of these advantages I figured it was worth the try. One other thing I really liked was the fact that these brackets position the coils away from the down pipe so I don't have to worry about any wires burning over time.

Up next:

Clean and prepare clutch, flywheel, and trans

Wiring for ignition coils

Re fabrication to the down pipe for new turbo

-

On 3/8/2023 at 7:52 AM, KaiserRolls said:

New crank sprocket and chain takes up a lot of the slack, did the same thing instead of installing a tensioner

I see a lot of people still running a tensioner even with new sprockets and a chain but I thought it was unnecessary when I felt how much chain slack there was.

-

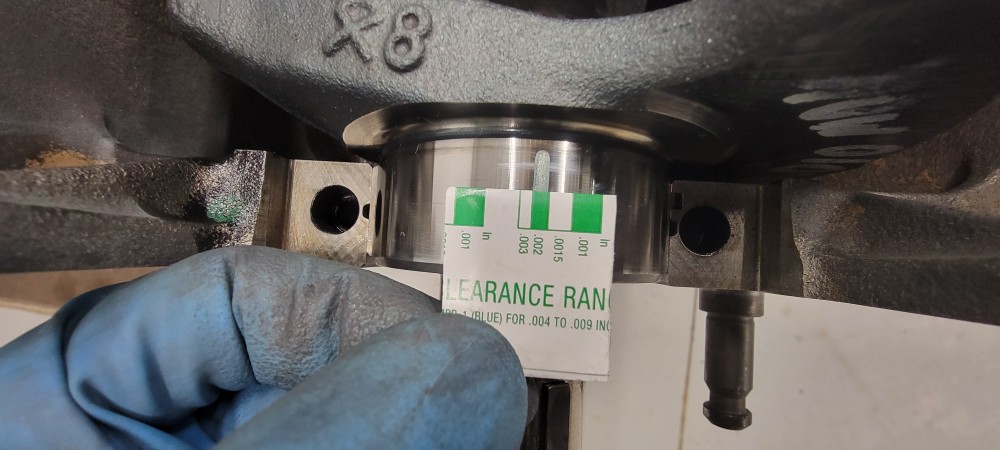

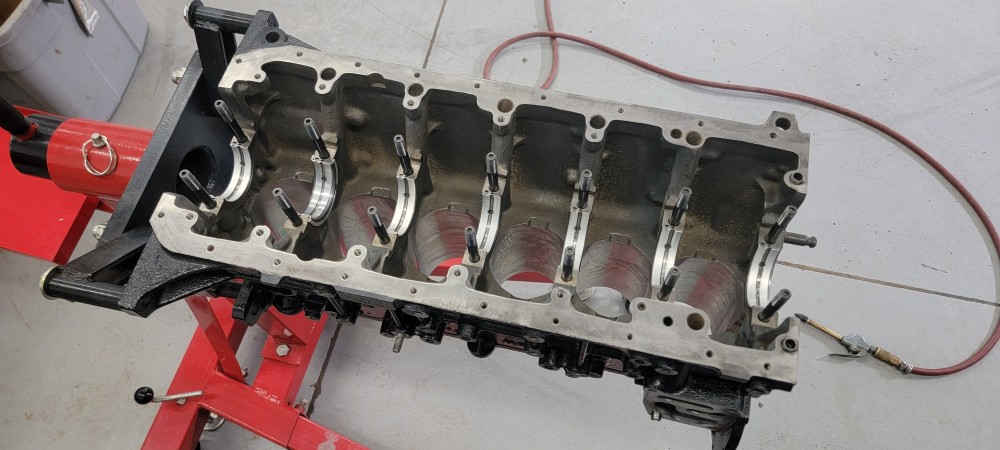

Got the crankshaft back from the machine shop. They got .010 removed from the thrust services and the thrust bearings fit much better now! With that figured out I got to measuring all my main bearing clearances.

All seven mains came in at .002 clearance which was right within spec so I was good to get things lubed up and installed permanently.

So something that I did with the last rebuild which I decided to change up this time was involving the arp main studs. Straight from arp when you receive their set of main studs they end up being too short and the nut only engages about halfway. On the first rebuild I dropped small 1/4" ball bearings in the holes to raise the studs and be able to bottom them out. I wanted to look into this a little further then I had and see what arp actually recommends to solve this issue. Two options... Back the stud out tell you get full thread engagement or ditch the washers. After reading through what a lot of others have done it seemed the option used with the most success was just ditching the washers. So I did just that. Torqued them all down and followed the proper torque procedure and checked my crank end play with a dial indicator which came in right at .003, right within spec.

With that complete I moved on to assembling the connecting rods and pistons. For this setup I chose JE for my pistons and got them in a lowered 9:1 compression ratio. I plan to run this on a flex fuel setup so I wanted the extra room for pump gas. As for the connecting rods I chose a set of H beam rods from Molnar technologies. The fit and finish on these are very nice and will fit my power goals nicely.

Time to start dropping them in the block. In the past I've used an adjustable piston ring compressor for piston installs. There is a lot of headaches that come with using one of those and I wanted this to go nice and smoothly so I purchased a ring compressor specific to the bore spec. It was well worth the extra money spent as they made this part of the install a breeze! I also wiped all the cylinders, piston skirts and rings down with some marvel mystery oil prior to install as recommended from JE.

Checked my rod bearing clearances as I went a long and all six came in at .002 which was right in spec.

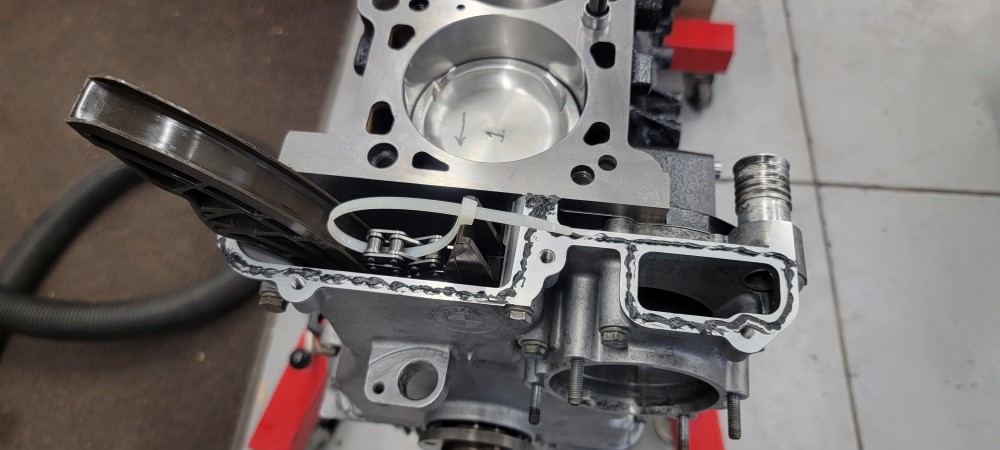

With that complete I moved on to installing the windage tray and oil pump. I got a new oil pump chain and crank sprocket which paired with the Achilles sprocket really tightened up the chain slack.

New guides and timing chain installed as well.

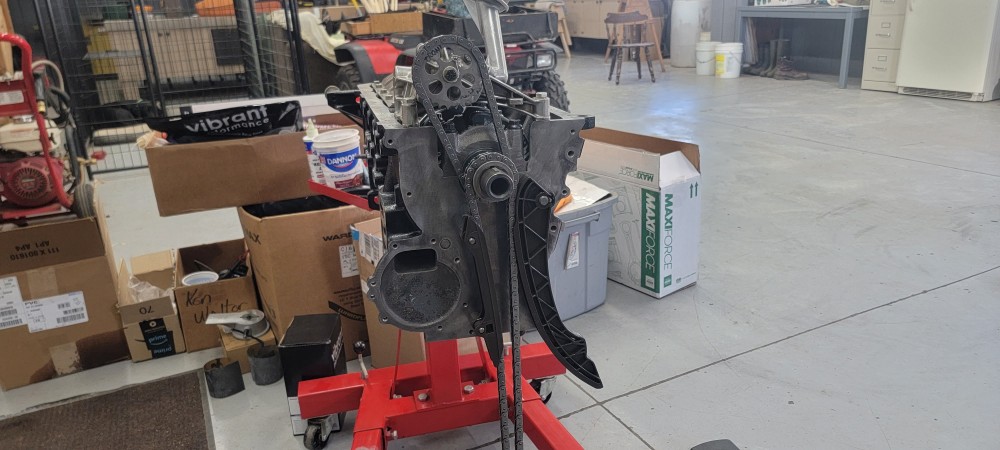

I got the timing cover installed as well as the rear main seal and all hardware for those torqued to spec.

On the previous motor I had my fair share of oil leaks, especially around the pan gasket area. Unfortunately when I had the baffle and turbo oil drain bung welded on it slightly warped the pan gasket service. I figured this will most likely continue if I used an oem gasket again. Instead I decided to ditch the gasket all together and run a small bead of the right stuff gasket maker. I have used this stuff in the past and it works really really well and should help fill in areas where the services may not sit completely flat.

Next on the list. Start getting the head prepped and ready to be installed!

-

On 2/19/2023 at 6:15 PM, timmer said:

Nice work! It'll be nice to see the car on the road again, all this work going into it is gonna make it so much better.

Every time I see your car, I get the forced induction bug for my S52! Lol

Thanks! I am very excited about this one. Going into this for the second time realizing all the mistakes I made on the first rebuild on top of all the knowledge I've accumulated on these engines over the years is hopefully gonna make for a much more solid power plant.

-

And the start of a new chapter begins...

After further consideration of my plans for putting back together the M52 I had picked up and throwing that in, I decided against it, rolled the car back into storage and let everything rest for the remainder of the year. Although the bottom end seemed alright to run as is, I felt foolish doing it and didn't want to go through all the time and effort of putting it back together just to possibly run into issues right away.

As things sat I slowly began acquiring parts needed for a full engine rebuild. I brought the old s52 block into a local machine shop to figure out what my options would be for piston size. After doing an inspection of the cylinder walls they said I would need to bore the cylinders 20 thousandths over which left me with going to an 87 mm piston. Initially I was good with this but after seeing possible issues with others having cylinder walls crack on them as well as not having any wiggle room with the cut rings on the HG and running into valve and piston head interference's I threw that block back up on the shelf and re-considered my options. Thankfully I had an M52 laying around now which gave me the option to run the piston size I wanted to so I landed on using that block for the rebuild.

Fast forward a few months and the block, pistons and rods were dropped off at the machine shop as well as an s52 crank that I purchased a few months prior. Unfortunately the crank main and rod journals were in rough shape and required a .010 grind and polish. I also had the machine shop do a re-balance of the entire rotating assembly. As for the block, it was bored out to 86.5 mm and honed with a torque plate installed afterwards. block was also decked with the timing cover attached and line honed for the upgraded arp main studs.

As for the cylinder head, I brought in the head that I got with the m52 and had the shop check the deck for straightness as well as vacuum testing it and pressure testing to see if it would need a valve job. Thankfully everything checked out good there. Had them run that through the hot tank to clean everything up.

Other machine work I had done included having the rod clearances checked and sized for the wrist pins and the cam shafts being polished up as they were a little scored up on the journals.

Everything when I got it back from the machine shop a few weeks later...

After spraying the entire block down with mineral spirits to remove all oils used for flash rush prevention it was time to paint the block

coat of primer first

Was pretty happy with how that turned out.

Assembly time rolled around and I ran into a small road barrier right away. First thing on the list was installing the oil squirters. I went through the six squirters I had from the blown s52 and used a small pick to test the spring pressure on each one. All of them had very weak or no spring pressure. So I dug up the six that came with the m52 and tested those. I found four of them that seemed to have fairly good pressure while the other two were very weak. Instead of just replacing the two bad ones I just ordered a whole new set of six.

With the squirters on the way I went ahead and got the main bearings installed so I could get the clearances checked.

When I went to set the crank in the motor I noticed it did not want to slide into place and was getting hung up on the thrust bearing washers. Pulled the crank out to see if I was missing something but after pulling the bearing out and attempting to place it on the journal I found there was no way it was going in and was larger then the width of the journal surfaces by a good amount.

Gave the machine shop a call and found that they had not ground down the thrust washer surfaces as they were unaware that the thrust bearing was a one piece design instead of the more common multi piece style. The oem .25 mm undersized bearings I ordered also make the thrust washer area undersized instead of keeping it oem size. After some extensive researching I was unable to find a thrust bearing on the market that came undersized but held the oem thrust washer thickness. So the crank needs to go back into the shop so they can grind that up correctly.

With me unable to do anything with the crank I switched gears and began the tedious process of gaping all my rings. Went with a slightly wider gap then oem spec for boost reasons.

I did have a hard time with my newly purchased ring gaping tool and on my first go around I messed up a top ring for cylinder #1 leaving me with too wide of a gap requiring me to order another set for that piston. Thankfully another ring set was fairly inexpensive. After that one I got a feel for how fast it took off material and the rest of the rings went pretty well.

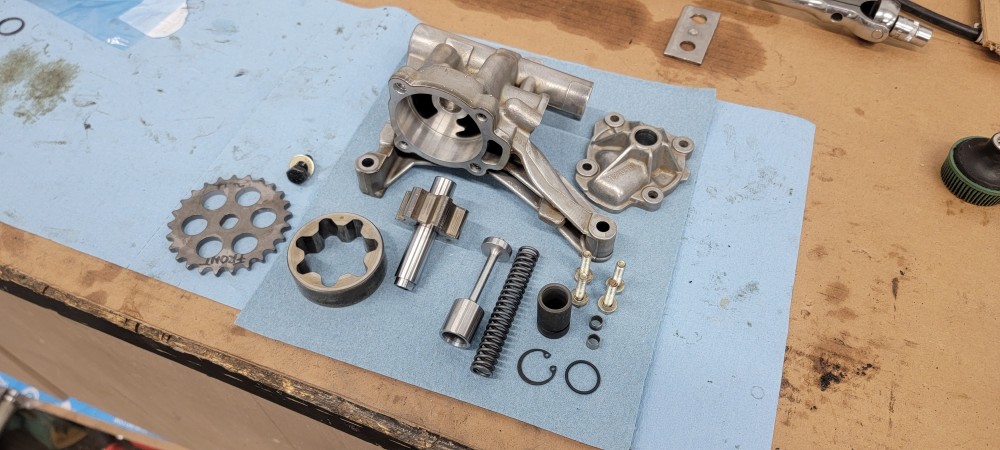

Afterwards I switched gears and worked on getting the oil pump ready to go. Original plan was to reuse the oil pump from the blown s52 but after pulling the rotor out I found there to be quite a bit of scoring on both surfaces making the pump unusable.

Dug out the oil pump from the m52 block and found everything to be in much better shape and score free!

Purchased the Achilles upgraded oil pump shaft kit to go along with it. Went ahead and got the old shaft pressed out and the new shaft installed and set at the correct distance.

Also took the time to clean up the pump housing a bit and remove all the oil staining. Decided while I was in there I might as well do a full rebuild of the pump with an all new control valve, spring and rubber washer.

Once everything was lubed up and installed I got the pump primed and ready to go.

As for now that's all the progress I've managed to get done. Hoping to get the crank back to the machinist by Wednesday and maybe see it back by the end of the week or early next week so I can really get the ball rolling.

-

And as always, bad with keeping up with the updates on here.

Well not to long after I determined the motor was gonna need a full rebuild I got to ripping it out and getting things disassembled and ready for rebuild.

Other then the bent valves and scored tops of pistons/cylinder walls, the rest of the rotating assembly looked pretty good. Everything was torn down and boxed up for storage. As for cylinder walls and other bare metal surfaces I sprayed a layer of wd-40 over everything for surface rust prevention.

Originally I had intentions of diving into this and begin ordering parts/getting stuff machined to maybe have it up and going this year still but for financial reasons and being that I have a few other more important priorities right now I decided I'm gonna hold off for now.

In the mean time, I had some new door seals for the car that had come in a while back and decided to swap the old ones out. I didn't get any pics of them but the original ones were in rough shape and had holes all along the bottom portion. Water would leak in from time to time when I washed the car or it rained. It was also pretty easy to hear the outside wind and cars passing when on the highway which was getting pretty annoying so this was well overdue.

After finishing that up I gave er a good wash and topped off the gas tank. Also added another bottle of ethanol stabil treatment, seems to be doing a good job at keeping the e85 in somewhat good shape so far. Afterwards the car was parked back in storage.

I had a shelf on the other side of the shop where I was storing all the boxes with the motor parts. As for the crankshaft I had it wrapped up with plastic wrap and stood upright on the shelf cornered in by three other boxes. It was done that way in case it became unbalanced and fell it would only fall onto the cardboard. Unfortunately I hadn't made my grandpa aware of this right away and the following day he started moving the boxes of parts around that I had placed around the crank. This also caused the crank to become unbalanced and fall over and drop five feet to the concrete where it snapped in two. I am thankful that it fell on the ground and not him but I am now on the hunt for another crank.

And up tell about two weeks ago that's all that had been going on with this car.

For a period of time I had the idea of finding an m52 for cheap and throwing it in the car to still enjoy it for the summer. Unfortunately prices seemed to have go up quite a bit for those now so I kind of tossed the idea out.

Well a friend of mine messaged me saying he had an m52 he was gonna use for his car but ending up going with something else and said he would sell to me for cheap so I went and took a look at it.

I ended up bringing it home with me.

The motor was pulled apart because of a valve keeper popping out of place and dropping the valve in to the cylinder. At first I was hesitant about it since I figured the walls would be scored and would also need a rebuild which I was not looking to do with this. After looking it over I noticed no scoring on the walls of that cylinder (ran my finger nail around it) and the rest of the five cylinders looked fine. He also had it looked over by a few people who have built quite a few racing engines and said he would be fine running it.

Everything to turn this into a long block was included as well as some new gaskets. There was also a fresh cylinder head done for it that was hot tanked and decked, ready to be installed. On top of that he threw in the cylinder head that was originally from this motor which was missing the one valve and a few cam studs but the rest of the valves were in good shape and would be a good parts head for the s52.

Rotating assembly spins freely and smoothly by hand and just to be safe I pulled the piston out and inspect it. From what I can see it appears to be fine and I saw no major damage besides the scoring on the face.

So far this was my plan with this. Pop the piston back in and leave the bottom end as is. Check the block surface for any warpage and if there is any (I'm guessing there most likely will be), re deck the block using the wet honing stone method. Re seal the motor running a stock headgasket, and some arp head studs and see if I can't run high 300's on e85. This would only be a temporary motor to get the car back up and going tell I can start rebuilding the s52.

Sort of a budget build you could say.

-

6 hours ago, SteelBlue said:

Pain.

What actually causes the valves to contact the piston? When it over rev's, it exceeds the limits on the springs and the valve extends further than it should contacting the piston?

Ya I imagine the valves stretched a bit at the higher rpm and the cam spun faster than the valves could reciprocate, causing the valve stem to separate from the cam during the close cycle.

-

-

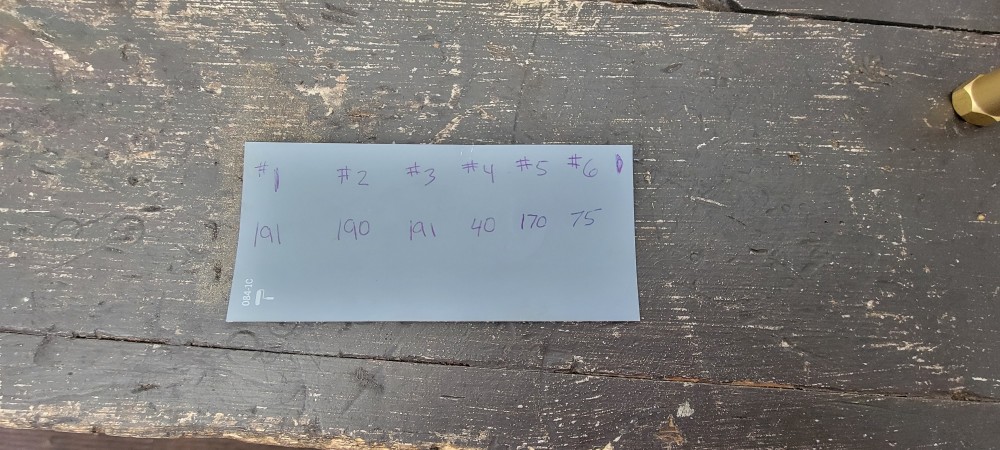

Mistakes were made this past weekend 😔

Pulled the car out of winter storage on Saturday. After taking it out for a little shake down I went for a ride over to a little local car meet going on. Well one thing led to another and here I am on the highway doing a few pulls against a couple quick cars. Downshifted down to 2nd... 3rd, went for 4th and instead grabbed 2nd again and dropped the clutch. Car banged the rev limiter once or twice before I got the clutch depressed again. As I'm rolling in neutral I checked my gauges, still got oil pressure and the engine is still running and sounds somewhat fine so I continued to drive along another half mile tell I found an exit to pull off. Came to a stop and I find myself driving to what seems to have about the power of a 3 cylinder. Luckily my buddies house was only about a mile up the road so I slowly limped the car, which still had good oil pressure, over to his place and shut it off. Got a ride home and the following day I came back with the truck and trailer and hauled it back over to my grandpa's shop who was less then excited to see it back so soon.

Right off the bat I whipped out the old trusty compression tester and started cranking.

After seeing my low compression numbers on 4 and 6 I drained the oil and pulled the filter to check for metal pieces or shavings.

Oil looked clean and normal as well as the filter so that was at least somewhat encouraging.

checked out each cylinder with an inspection camera and found that none of the piston heads appeared to have any markings from a valve hitting them.

The quality of the images aren't the greatest so I can't be 100% on anything but it was nice to see the possibility of no valve damage.

As of right now i'm thinking one or more of the following things happened:

Bent connecting rod

bent valve (but seeming less likely after what I found)

blown headgasket (it was just an oem one)

or recked piston rings

Things to consider: When I pulled the car into my buddies I shut it off and restarted it in which it fired right up again but was of course misfiring and had a slight knocking noise from the bottom end. I can also spin the engine by hand no problem and it doesn't feel like there is any binding.

Gonna try to start disassembly and removal of the head tonight.

-

Few parts I've had laying around and no longer need.

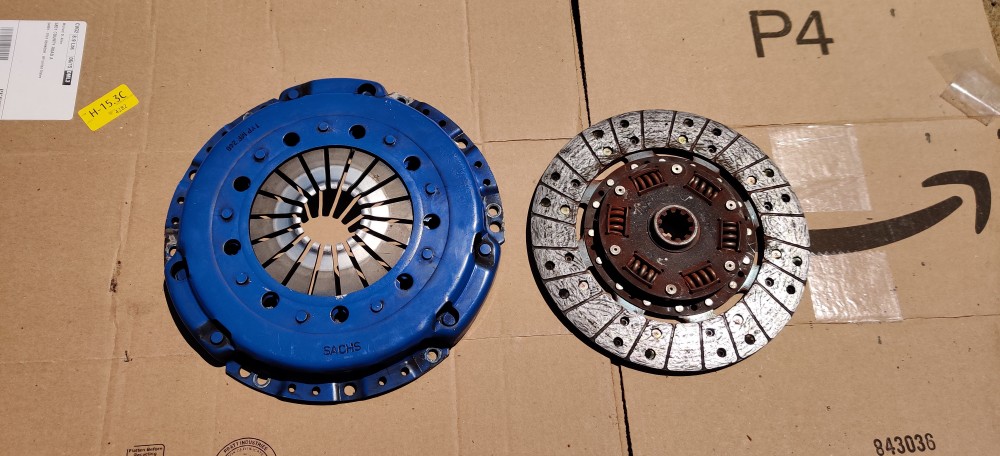

Fx-racing stage 2 clutch and pressure plate. Less then 3000 miles on them. $100 obo

E30 24 valve swap ebay headers. They have been modified at the end to fit the e30 chassis a bit better. Has a ceramic coating on them but is peeling off. $50 obo

Holset hx-35 turbo. Spare turbo I bought that came out of a school bus. Unknown miles but has minimal shaft play. $100 obo

E36 obd2 valve cover gasket. Bought by accident. Brand new in packaging. $10

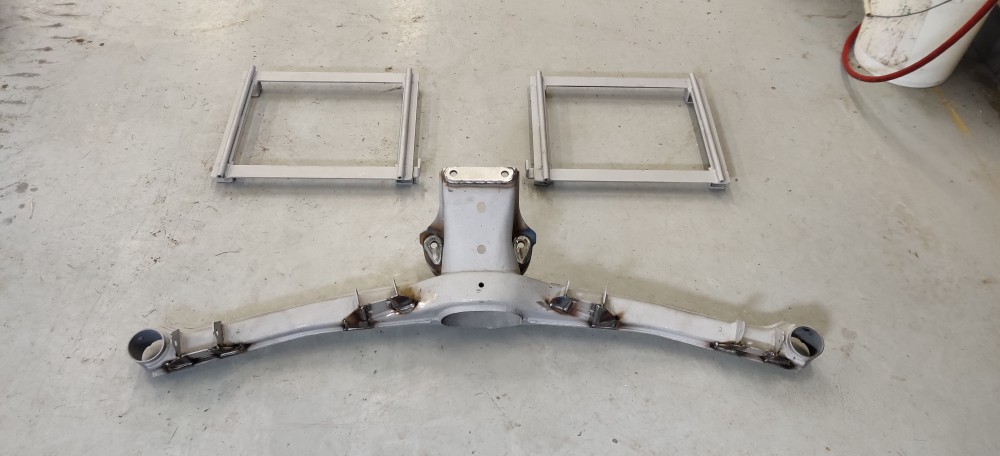

Bmw E30 rear subframe. All garagistic welded reinforcements (diff mounting points and trailing arm mounting point gussets). Also has the full eccentric adjustability for camber and toe. Was sandblasted and then three coats of por-15 was applied for protection. $SOLD

Lmk, thanks!

-

Well I figured it was time I come back and update this thread lol. Last season was an absolute blast with this thing. I got a fair amount of seat time in and got a better grasp on controlling the car and it's power.

(FVSCC auto-x at the Waupaca airport last year)

Other then regular maintenance and up keep I didn't do much to the car in terms of upgrades. However, I did end up having a stone hit the windshield causing a small crack on the lower passenger side. On top of the crack there were many scratches all over and it was beginning to become a pain to see through (it was the original one). So I set up an appointment and had it replaced by Tri City glass and door up in Appleton. They did an excellent job and I was very pleased with the finished product.That was about it. After the last auto-x in October I enjoyed the car for another week or so and put it away in storage for the season. Unfortunately I was unable to gain access to my grandfather's shop over the winter to work on it and I had a lot of other things going on that I just wasn't gonna have anytime to work on it anyways. I shared a cold storage unit instead with my cousin where it sat for the winter.

March rolled around and I started thinking about the upcoming warm weather and what I wanted to improve on the car before I started driving it again. Seats were the biggest thing on my mind as I still had the old ones that were getting pretty bad to drive in and I had a hard time getting comfortable in them. I was set on finding a set of Recaro srd's. I knew that was the set I wanted in the car and I did not want to compromise for anything else so worse comes to worse I was willing to drive with the old seats a while longer tell I found the right set. Well after several weeks of watching marketplace and other bmw pages/forums I came up with nothing. It seemed that the only sets that were going up for sale were selling within a few days and fetching to high of a price for the condition they were in. I gave up on looking in the midwest area and for shits and giggles started looking around the whole country to see what would pop up. Sure enough a set popped up In Denver, CO. The owner had them mounted in a mustang but sold the car so the seats had to go. I jokingly shared the ad to a friend of mine asking if he wanted to do a road trip to pick these up in which he replied "lets do it!" Over the following days since I had talked with him I thought it over while messaging the owner to see if he would be willing to hold them with money down tell I got out there. He agreed and that weekend my buddy and I made the 32 hour round trip to go pick these seats up.

He was the original owner of this set and had taken very good care of them. On top of that he was including wedge brackets and sliders that he used to mount them in his mustang.

Being that a new set of brackets and sliders were gonna run me upwards of around four hundred bucks for both seats I wanted to see if I could make the mustang ones work first. I took some measurements of the bolt hole distances and what I would need to modify to get them to fit properly. The following day I took them over to a friends and we went at modifying the brackets to fit the car.

The next thing was to figure out how I was gonna get the seat belt buckles to mount. I liked where the mounts were originally but with the e30 buckles it was not gonna work. In order to keep the location and fit the buckles I cut down the vertical piece of metal in half and drilled and tapped a new hole for the bolt.

I ended up snagging some 5/8's size bolts from my grandfather's spare bolt bins at the shop and hacked them down so they were smooth without the outside surface. Worked like a charm and I mounted the seats back up to confirm there was no rubbing with the new set up. All that was left was to get them sand blasted and repainted.

I put one coat of etching primer and two coats of SEM black trim paint.Purchased some new stainless hardware to bolt down the brackets to the car.The fitment of the seats in the car was exactly what I had hoped for. The fact that I sat lower and could slide back further to get more comfortable and secure in the car was awesome! These definitely were a game changer for the cars comfort and secureness. I can't wait to put these to proper use!

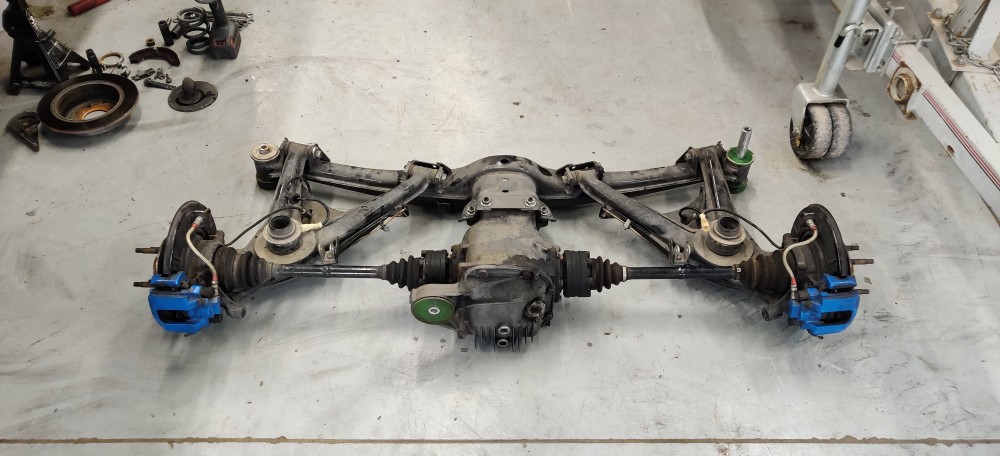

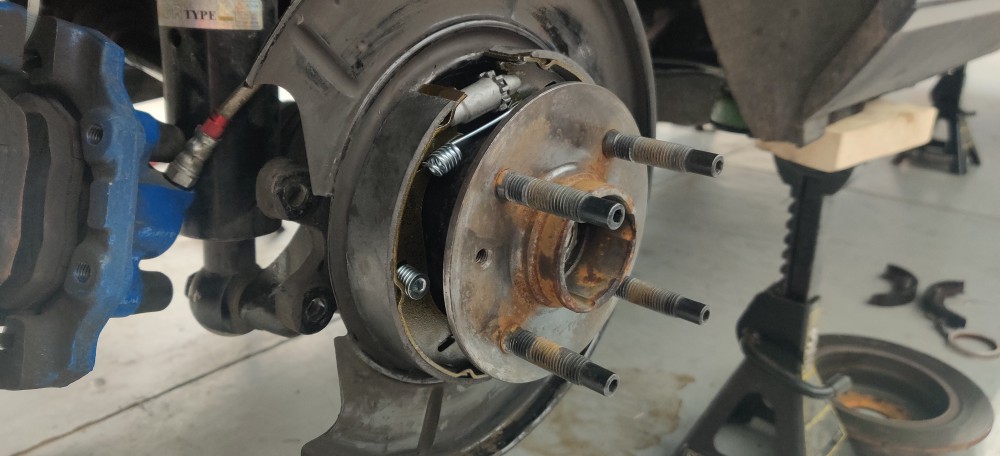

After I finished those up I switched gears and started working on a spare sub-frame I had bought the year before. After having enough trouble with not being able to adjust the eccentric bolts I had in the rear (because of the raised sub-frame bushings) and driving the car with something like 2 or 3 degrees of toe out on one side and 1 degree toe in on the other was nothing short of a headache. Same went for the camber adjustments in the rear. I came to the conclusion that I need to swap out the rear sub-frame all together for another one and do everything besides the adjusting bolts. The spare I had was pretty rusty and still had the old rubber bushings in it.After taking an angle grinder and wire wheel to knock off most of the big chunks I sent it in to be sandblasted. I had ordered some new reinforcements for it from garagistic which included the differential mounting holes and trailing arm plates. Once I received the frame back from blasting I brought it over to my friend's place to get welded up.Time for a little por-15 for protection!A few days later the car was brought to the shop and I went to work pulling the rear end out. Took me a whopping two hours to pull it all out. It sure is nice when things come apart nicely.When I had everything apart I went ahead and re-greased the RCAB's and sub-frame bushings as they were already pretty dry from last season. Once the new sub-frame was bolted in and torqued down I went ahead and changed the diff oil out. Checked the old oil for any metal shavings or odd debris and then added some fresh Castrol Syntrax 75w-140.Rear end was popped back in the car afterwards and I swapped out the e-brake shoes and springs with some fresh ones.Over the summer last year the e-brake got left on by accident once or twice while driving the car. That just about roasted the shoe pads off to the point that it no longer could hold the car on a slant. Thankfully those parts were ordered through fcp euro so I went ahead and took advantage of that life time warranty.Once I was done torquing the rest of the bolts down holding the rear end in and inspected everything thoroughly I bled the brakes flushing out the system and added some fresh ATE typ 200 brake fluid.Switching over to the engine side of things I pulled apart the exhaust system and re-wrapped the down pipe and a section of the exhaust pipe. The old wrap had tore in a few places and wasn't looking to great.Ordered some Design engineering titanium wrap as a replacement hoping it will do a little better job at reducing exhaust temps in the engine bay.The kit I bought came with clamps and a tool for easily tightening them down. Unfortunately it took me a few to figure out how tight I could go before the clamp would break so that was a learning process but overall I was very pleased with the finished look.After that was back in and installed I did some maintenance related things: Changed the oil and filter, pulled the plugs and inspected/gapped them, and thoroughly cleaned the under side from oil and grease. The following day I took the car into town for a good wash and detail.I am working on possibly ordering a new breather setup for my pcv system. The catch can I'm running on it currently is sort of a cheapo and is doing a lousy job at filtering out the fluids so I'm looking into something a little better. Also would like to get the car back to the tuner at some point and get a 93 pump gas tune made now that I have a flex fuel sensor in there.Other then that the car is running great! Definitely looking forward to the upcoming season!- patsbimmer1, jc43089, P_Roloff and 1 other

-

4

4

-

So I fixed/improved a few things on this car a couple weekends back. Even though I had thought I had fixed it entirely with the turbo drain line I have still been having some oil leaking issues lately, Just couldn't pinpoint where it was coming from. After some close inspecting I had reason to believe my valve cover gasket was leaking. A few days later a new valve cover gasket appeared on my door step and I spent an evening swapping them out.

After that was finished I started the car up and began inspecting. That's when I noticed something after bumping the oil feed line for the turbo...

You can also see that the 90 on the -an fitting had been kinked. I knew about this prior to the leak but new that oil still flowed through it fine and kind of just put it off. well sure enough that's where the leak was all along. When I lifted the line ever so slightly it would begin dripping drastically. After spending a few hours searching around I ordered a new -4 an line from rally road. Also, after some more inspecting I found that the oem breather fitting coming out of the valve cover wasn't cutting it anymore and blow by was getting past the fitting and making an oily mess underneath. While on rally road's site I also found that they sold a fitting to fix this exact issue so I ordered that as well.

A week later or so and the fitting and line were here. The following day after work I got to installing the new pieces.

Old line vs. new

Unfortunately I could not find a -4 an line in black which would have been a little more ideal looks wise but it is what it is.

New breather setup installed.

The rally road breather fitting was an awesome piece! It has two o-rings on the shaft that slides into the valve cover hole which sort of snaps into place, its a tight fit. Coming out of the other side is a -an fitting so I ordered a -10 an 90 with a hose barb on the other end to adapt to my rubber hose running to the catch can. I love the look of the new setup and best of all, no more leaks!

After all this was finished I figured it was also about time for an oil change as well. After some debating back and forth I figured it was time to switch over to synthetic. I had been running shell t4 15w-40 for the last 12,000ish miles with a zddp additive and I had been doing this partly because of engine break in reasons and the fact that if I switched to synthetic that the leaks would get worse. With the new fittings and valve cover gasket I felt much better about making the switch. I chose a t6 5w-40 full synthetic oil.

Underneath the car was an oily mess so after completing the change I pulled the skid plate and used about 4 cans of brake clean spraying down everything top to bottom. Two weeks later and no signs of oil leaks anywhere!

For the longest time I had been running stacked washers to space the nut out for the momo hub instead of buying the oem spacer. Well when i ordered the valve cover gasket I threw it in with and decided it was time to swap it out for the right part.

The spacer was a few mm longer then my washer stack and actually fixed a steering wheel squeak I had been dealing with sometime now so that was neat!

First auto-x of the season for me this weekend. Looking forward to seeing how the car feels on the track with the new gearing setup and a non-squeaky steering wheel.

-

-

21 hours ago, GunMetalGrey said:

That tire is criminally low on tread!

Though I certainly know why!

What kind of seats are you looking for? E30 sport seats, or other?I currently have the e30 sport seats. It seems there is always something breaking on the brackets with them, their support during auto-x have been iffy at best and they don't really sit as low as I'd like. I was originally looking for something with a fixed back but now that I have figured that this car will most likely see more street driving then track or auto-x I have been on the hunt for something that has good support for the occasional auto-x track days but also the recline-ability and comfort for longer drives and cruises. Through my shopping around and research I have taken quite a liking to recaro srd seats but its been a struggle to find a pair reasonably priced and in the area that don't get sold within a couple days. I am of course open to any suggestions or recommendations if you have any.

11 hours ago, SteelBlue said:Good to know on the R1R's, they were the ones I was also looking at.

As you said, there is very little in terms of selection for this size tire.

The only other good option was the dunlop direzza ZIII which I haven't tried yet but they were gonna be around $50 more for a set of 4 and the toyo's had all the same ratings and was considered the better performing tire in rainy conditions which I can vouch for from the hand full of times during wet auto-x's when I didn't think I'd have any grip and they proved me wrong.

the one and only e30 s52 engine swap

in Members BMWs

Posted

Last Wednesday I took a drive down to Chicago and finally picked up the car!

The dyno tuning had been done a week and a half prior to that but they wanted to further dial it in on the street and work out any little drivability issues it had. As for power numbers, on pump gas it made 401 whp (not sure on torque numbers for that). As for E85 though, the numbers were a bit more shocking... in a good way

I did end up driving it back from Chicago and besides the 105 degree weather I baked in, it was a pretty enjoyable drive home. The car felt great and the engine didn't skip a beat. I will say though that the clutch is a little more difficult then it use to be. Especially when getting the car rolling in first gear. The one in there is technically only rated for like 480 lb ft torque so we'll see how far that gets me. There are a few things I wanna take care of on it like an oil change and address a few small things but other then that very excited to have the car back to enjoy the little bit of warm weather we have left.