-

Posts

2584 -

Joined

-

Last visited

-

Days Won

114

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Bassboy3313

-

-

-

13 hours ago, HipMF said:

DM sent. Still have my compact sitting here with a blown headgasket...

Where'd you get a deal on the 3L? Do they have more?

I have a feeling it was this guy.....

https://chicago.craigslist.org/nch/pts/d/trevor-bmw-330i-330xi-parts-part-out/7279203117.html

-

-

4 hours ago, HipMF said:

DM sent. Still have my compact sitting here with a blown headgasket...

Where'd you get a deal on the 3L? Do they have more?

It was a guy on craigslist in Trevor, WI, close to IL border that had a couple storage garages full of parts. He's always parting out different bmws and has parts galore. I can look at CL again and see if he has another post to get contact info.

-

1 hour ago, Rekpoint said:

Did you use metal rescue on the aluminum stuff like the pulleys, Vanos unit & oil filter housing? Or was it that clean to start?

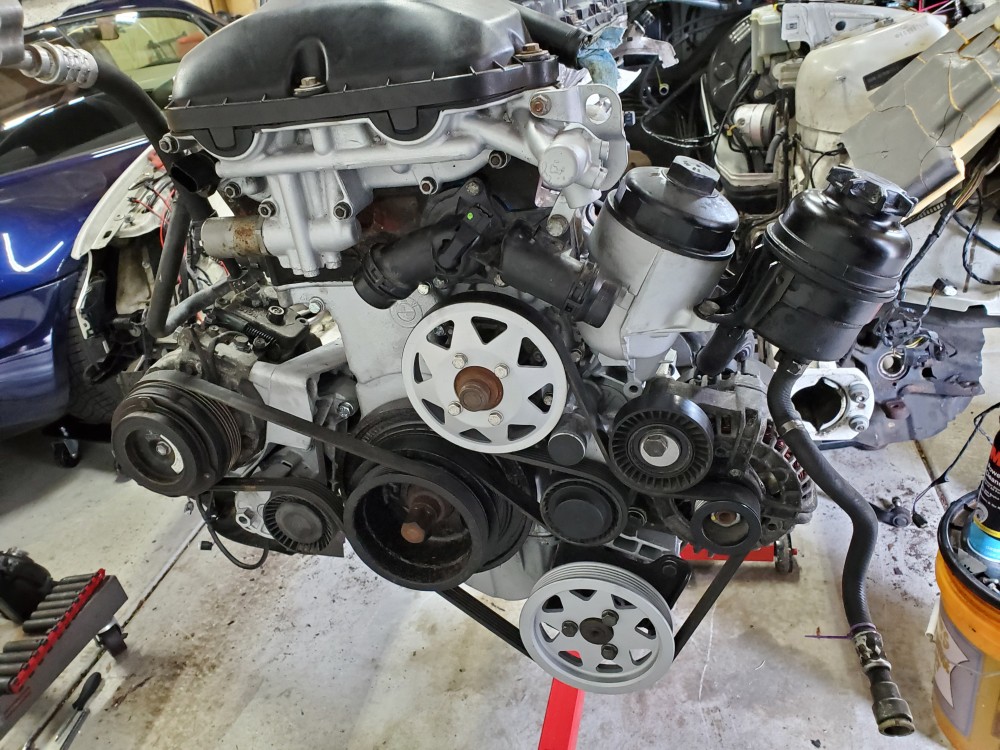

Those were all degreased, blasted and powdercoated silver.

-

The metal rescue rust removal bath worked great! The exhaust manifold studs came out looking like new and the broken downpipe studs were cleaned enough to be able to be heated with a torch slightly and air hammered out with ease. I will just use a nut/bolt combo for the downpipe flange connection to make things easier. Exhaust manifolds back on the engine with new gaskets and upstream o2 sensors. Also installed the SAI block off plate on the engine as well as I dont plan on putting that back in.

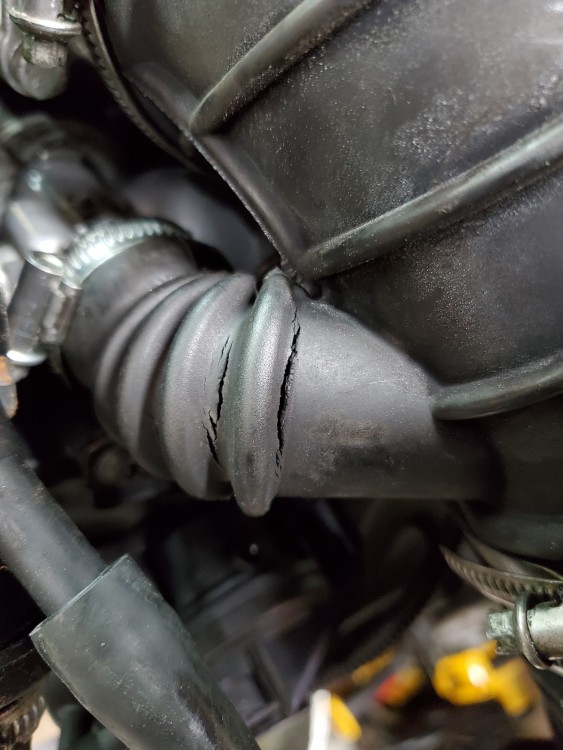

I started breaking down the passenger front axle due to a torn inner cv boot. Just gotta fill that back up with grease and clamp new boot on, then reassemble.

Also started getting the clutch lines and new slave cylinder squared away.

Replaced driver side engine mount and the old one was squished down pretty good. Surprised there wasn't any cracking in the rubber.

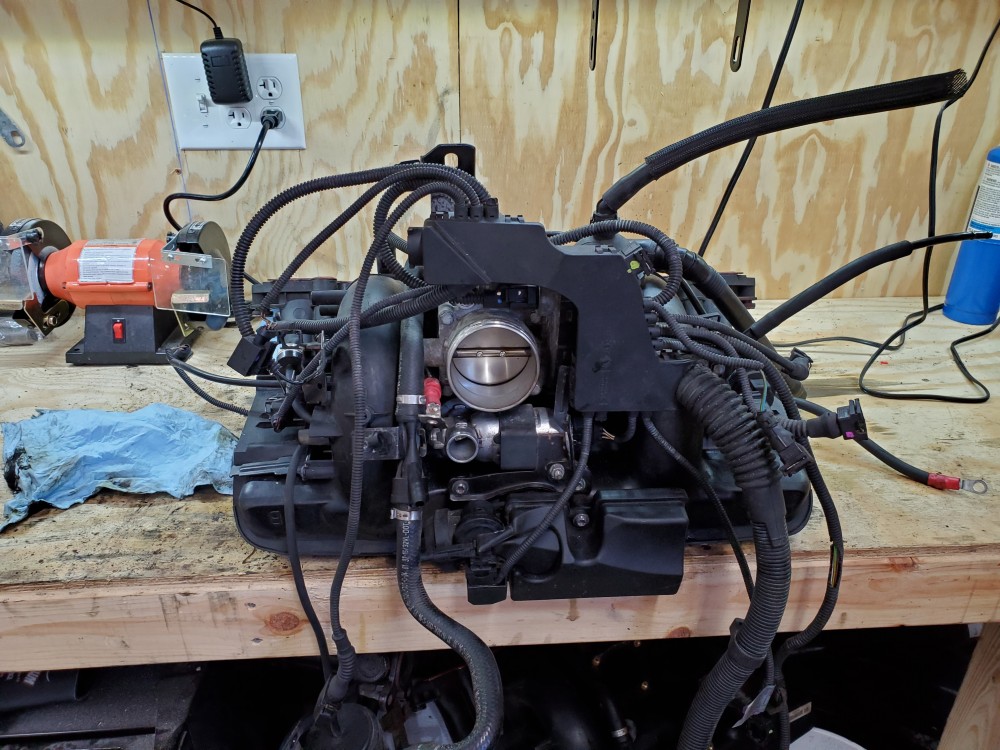

Then moved onto the dreaded intake manifold rats nest. I wanted to move everything that I could over from the B25 engine since I know that stuff worked well. Found a torn intake boot on both engines in same location (this could explain my misfire issue on B25). Will be ordering new boots along with new intake manifold gasket. I took my time marking every hose and electrical connector with different color paint markers while transferring things over to the B30 manifold. Hopefully this makes things a lot easier for reinstall.

And all done.

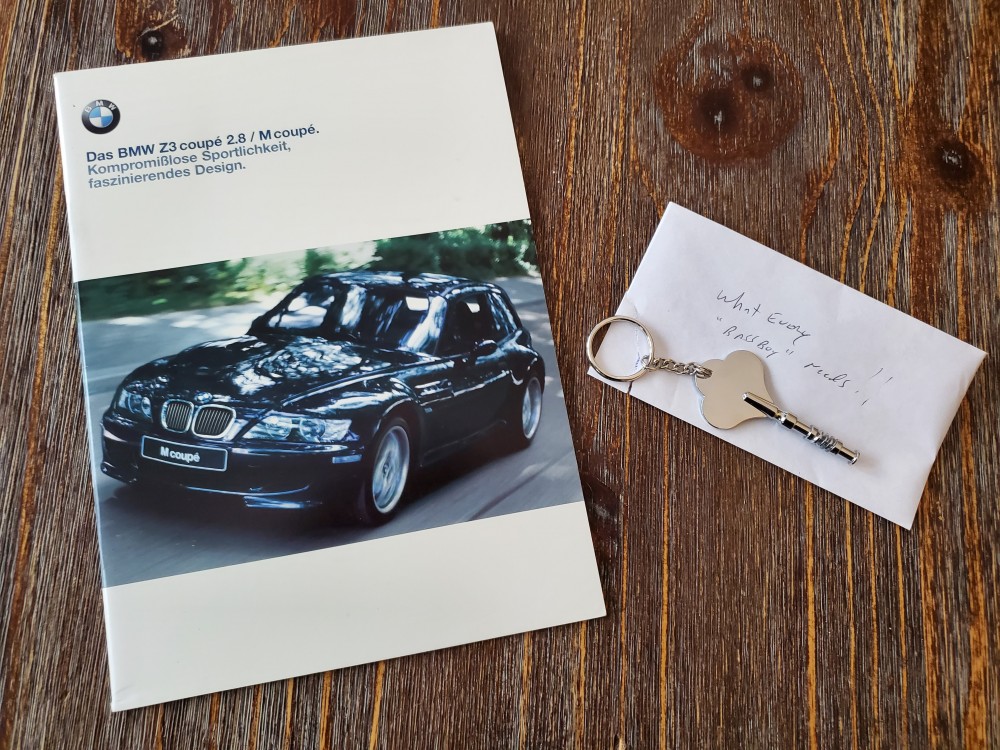

Anybody looking for an M54B25 to buy? Would be nice to get it out of the garage, so I can pull the Z3 Coupe out to stretch its legs. 😁

-

Front accessories mounted including the underdrive pulleys that came with the B30 engine. Working on replacing some rusty exhaust flange studs from the headers and slowly marking all electrical plugs before pulling the manifold off the old B25. Trying out some metal rescue rust dissolver. Letting it sit 24-36 hours and seeing what it does.

-

Engine & trans have been removed. Couple snags here and there but came out relatively easily. There always has to be an oil spill in one way shape or form as well. Found a bad inner tierod on driver side and a sheared control arm bushing bolt on passenger side from someone down the line before me. Hopefully drilling and an easy-out will fix that.

Next is transferring all the engine accessories over from old engine to new one, buying all new hoses/lines and prepping everything for reinstall.

-

23 hours ago, Rekpoint said:

Shameless plug. If anyone wants to see rare/uncommon BMW parts follow my instagram

https://www.instagram.com/bimmerbreakers.us/

Selling a lot of cool stuff on there. Also offering rare part finding services.

Do we get Wibimmers discounts on parts?

-

-

-

9 minutes ago, B C said:

how bad was removing the pedals?

It wasn't that bad actually. Put the seat all the way back and knelt on ground leaned in under dash. Hardest part was getting the booster arm off the brake pedal due to the metal loop that surrounds the pin on the brake pedal arm. Running the line to the slave cylinder will be a huge bitch tho as the carpet doesn't want to bend very easily to get to the grommet hole in floor/firewall. Might be a two man job for that one or waiting until old engine/trans is out to have more space.

-

-

-

- m42b32, Jdesign and patsbimmer1

-

3

3

-

-

Welcome! Looking forward to seeing this one in person sometime!

-

-

Welcome! Looks like saab wheels on the touring, no?

-

56 minutes ago, REKIII said:

Build volume is always a key factor in who you pic. Also, material selection and if you are using a dual head for soluable or break-away support.

Lets get some detes men.

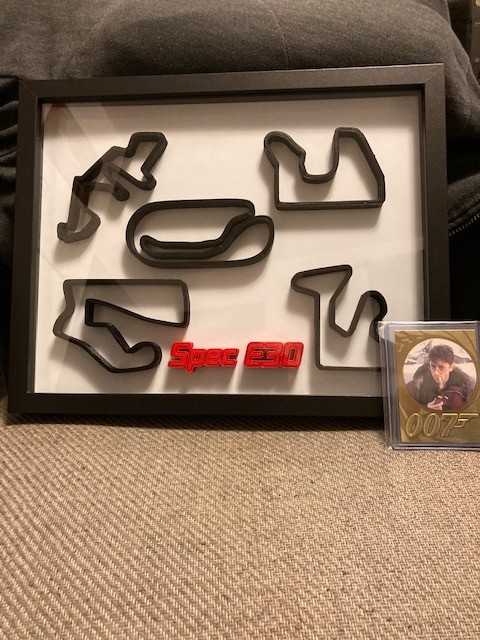

Mine is 200mm cube build surface. I use mostly PLA and PETG. In process of building an enclosure to experiment with ABS and ASA. Single head extruder with breakaway supports.

-

6 hours ago, Rekpoint said:

If anyone needs something 3d printed 4 cheeaaap feel free to shoot me a message.

E30 vent and OBC gauge pods

E30 switch delete plates

E36 A pillar clips

E36 radio delete / door panel repair kit (Top brackets)

318ti 5.25 woofer conversion brackets for the rear

Some of the stuff I've been experimenting with. Doesn't even have to be car related. I can print you a CAT FFS.

Friendly competition I see.

-

-

-

12 minutes ago, petemc53555 said:

Shameless plug for my own e34 shizz:

https://madison.craigslist.org/pts/d/lodi-bunch-of-1995-bmw-e34-series-parts/7246117940.html

Should probably be in the Parts for Sale category.......

E46 Touring Life

in Members BMWs

Posted

Thanks! I give credit to a friend of mine who enjoys cleaning. Me, not so much, lol.