-

Posts

302 -

Joined

-

Last visited

-

Days Won

13

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by Tkuhn

-

-

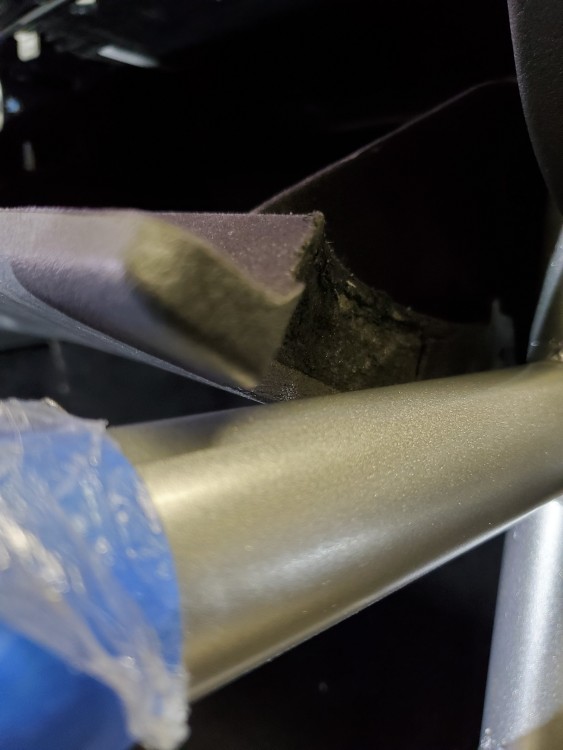

Not an update but excited to have another part come in!

S2rTuning sunroof delete!

Definitely seems like another quality piece to add to the car. Excited to see how the fit is this weekend. Really love that this is the only one I have found on the market that uses the existing mounting holes from the oem cassette to mount.

Fingers crossed that it fits well!

-

5 minutes ago, B C said:

love the updates man! Cant wait to see the overfenders on and wrapped

Thanks! Staying as active as I can and me too haha

-

Looking for a few parts from an e46 M3.

- fuel door

- passenger fender

- exterior door trim/rear quarter trim strips

Non-M parts.

- inside door sills that hold the carpet down (for a coupe)

-

UPDATE

Decided to bite the bullet and chop up the rear quarters.

Now it is worth mentioning that I did feel bad after looking at how clean this thing is lmao BUT it was only for a half hour and after I asked some friends to tell me to stop being a bitch 😅

So here is the last photo of the rust free quarter hahaha

And setting up to cut.

Chop chopped

Bent up and welded the folds.

Then filled all the gaps.

Then moved on to the other side. Only 2 photos of this side.

And finally finished off the day sealing them up with seam sealer.

Also the new chase bays handbrake set up arrived 😁

Thats it for now, next up will be undercoating the wheel wells and hopefully mocking up the overs.

-

4 minutes ago, Rekpoint said:

No. But a guy has a set across town from me had one and Im picking up some other things for earl. He requested them for you.

I appreciate that! I wish the dude had the door and rear quarter moldings. And the gas door lol

-

7 minutes ago, Rekpoint said:

Your soon to have m3 hood hinges !!

You had a e46M partout!?

-

Weekend update!

Started by getting the passenger and drive carpet buckets in. The carpet I bought from my part out guy was cut in the front because it goes under the heater core. So having them in 2 pieces works out better honestly.

Next up was cutting the dash in the upper and lower corners to fit with the cage.

I did cut more than I would like on the top so maybe down the road I might buy another dash and trim it better.

I also had to trim a little off the defrost vents for the sides.

Then trimmed the vents to fit.

Driver side. (Its also worth noting that usually the LCM does not fit, although I have some e46 buddies that figured out how to make it fit because the thing is GIGANTIC behind the face. Somehow mine barely fit without modifications. But I'm not complaining lol)

Here is the passenger vent trimmed to fit along with the airbag cover. I have another airbag cover that I might trim a little tighter since I know how it needs to be cut now.

Next I installed the rear carpet piece and trimmed it to fit around the cage.

I then installed the center console and arm rest I found in a junkyard awhile back.

In this photo you can also see the prototype v1 of the window switch insert Sam made me.

Pretty excited with how it looks and will function.

Then I moved on to trimming the glove box. Some say you cant make it fit. But with some info from another e46 friend and some thought it worked out great!

Here's the clearance with it down 😁

And some final photos of the interior for the weekend.

I was able to order my sunroof delete and the new handbrake set up so hopefully they dont take too long to ship thanks to this pandemic.

I will need to extend the window switch wiring so that is one of the things on the docket for next weekend.

Until next time!

-

-

UPDATE!

Started the weekend off on Friday night by getting the cage back up on the rocker boxes and welding them in for good then welding the cage in for good as well.

That task took all night and was definitely frustrating. But it's done 😁. Then I hit everything with some sandpaper in preperation for painting.

Saturday morning I got to taping and making off the entire car. Which took alot longer than I planned lol.

Pro tip: tin foil is a lifesaver and cheaper than tape and easier than plastic.

Wiped the cage down with some prep solution and then played down 2 coats of self etching primer.

"Pro tip #2" : I used my shop vac to try and keep over spray to a minimum and it did seem to work decently.

Obviously next came color! I did 2 coats of color and then a third to finish off the last can in the areas that will be "higher traffic" like the door bars and a pillars. I do plan to put down clear vinyl on the door bars to keep them from scratching as well.

I will spare you the repetitive photos and jump right to the ones with clear which I did on sunday afternoon.

I am super excited at the way this turned out.

Every aspect was daunting for me just because I wanted to do it as well as possible, since we pride ourselves on good looking and also functional drift cars haha.

I chose to use rattle can for a few reasons. With this tight area and the fact that I wasnt doing the entire interior a actual 2 stage paint with a gun would have made a huge mess with the air pressure and the hose.

Secondly if it does get scratched, which I'm sure it will, touch up will be easier if necessary.

And thirdly I do like to pride myself on tricking people to think that it was done with a gun but it's just spray paint lmao.

Super excited to un-mask everything and get rolling on putting the interior back in along with a few other projects for the season yet!

-

UPDATE

Started the weekend off with running down to a buddies in Waukegan to pick up a set of DonMusk M3 over fenders. Which I have wanted for a long time and timing worked out plus I saved huge not having to ship from Poland.

going to take some work to get them fitted right, more so on the end of opening up my wheel wells. The overs themselves fit great.

Then I moved onto passenger side door bars.

And after that was getting the gussets in for the door bars on both sides.

With the gussets being completed that was the final touches of the true fab work.

Then on to final welding!

Only pic I really took of final welds. Turned out ok.

The next step to finish final welding was to remove all 4 rocker boxes and drop the cage down to get to the tops.

That was about it for the weekend. Next weekend I am hoping to get the cage back up and in place, then weld the boxes to the car and the cage to the boxes and finally the daunting task of painting. Lol

- jc43089, Rekpoint and patsbimmer1

-

3

3

-

UPDATE!

Got some really rewarding progress done this weekend 😊

Had the windshield removed during the week.

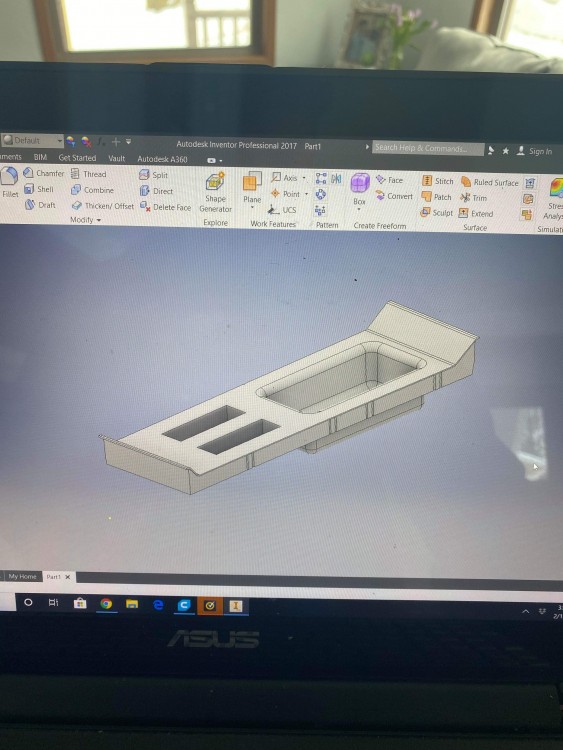

Then moved on go making my CAD rocker boxes a reality.

Next was the A pillar bars. Notching them was a real trial and error process but again super grateful to Sam for the help on these as well.

They fit really well and I'm happy with them.

Then I moved on to the door bars on the passenger side. Which turned out exactly how I envisioned them! Theres pleanty of ways to do a door bar but from day one this was what I wanted and I couldnt be happier.

Just need to add the verticals for more support.

And to further my excitement the door closes and fits perfectly with the seat and door panel!

Things are moving along so hopefully the other door bars go smoothly then final welding can commence.

-

-

1 hour ago, YoungCR said:

Fitment looks perfect 👍

1 hour ago, B C said:Very nice fab work

Thanks guys! Cant take all the credit for myself but we definitely are striving for getting as tight a fit as we can.

-

Update.

Been busy with some personal stuff but finally got some time to get to the shop.

Pulled out the main hoop and got it completely welded.

Which was a daunting task for me leading up to it. I can weld and do fab work but when it came to something this permanent I got nervous about my welding skills.

But it went well 😊 so confidence re-instilled.

Then I cleaned up all the seam sealer under where the rear box plated for the main hoop will be and re-tacked them in. Forgot to take a pic but it wasnt much of anything exciting.

Before putting the main hoop back in we "clearanced" the rear seat area with the good ole attitude adjuster. Aka hammer. The idea was to make room for the chassis harness to slide back down next to the bottom of the main hoop. Really excited on how that little detail turned out.

Next we threw in the main hoop and tacked it in place again, then I got the rear down bars properly aligned and squared up and did a final weld on them to the main hoop.

Hoping to make more progress next weekend!

- B C, Jdesign, patsbimmer1 and 1 other

-

4

4

-

Price drop. Asking $220 obo

-

Custom made e46 coupe harness bar.

I'd assume it would fit a sedan but it was not made in one.

Made of 1.75" DOM, Rods that go to the chassis are from an e36 harness bar.

Will come with mounting bolts and misalignment spacers to work with the heims.

You WILL need to trim your rear "door panels". I do have a set of vinyl dyed black originally grey panels that I could include for extra cost (color matches great) or I also am willing to sell a pair of uncut black panels for extra cost.

The harness bar is currently painted white.

Pickup in West bend or possibly Fond du Lac on certain weekends.

-

UPDATE!

Exciting weekend at the shop.

We started on the cage. So thankful for the help that Sam has given me already.

Main hoop fits nice and tight thanks to the added ability of Sam with solidworks to be as precise as possible.

And then we were able to get the cross bar with the harness bars situated in the right spots for harness angle.

Then the downbars for the rear. Kinda hard to see with the straps holding the main hoop up.

Super excited to continue the process of getting this thing done!

Oh and on a side note I also bought some new windshield washer sprayers for my tire sprayer set up to keep the tires cool after each run, the spray pattern gets the whole tire now instead of only 2 spots.

Here's a pic of the spray pattern.

- jc43089, Jdesign and patsbimmer1

-

3

3

-

-

So I've wanted to change my orientation of the handbrake for awhile now. I've seen a few people run the pull back style on the left of the shifter and use/make the window switch slot larger to accommodate for the throw of the handle.

Now that chase bays makes a pull back reverse mount handbrake I thought it was time to make it happen. Still need to order the brake but we have begun planning.

My biggest issue with what I want to do is most people just let the window switches hang. Which I'm not cool with lmao.

Of course this project began with some Cardboard Aided Design, I didnt take any photos of that.

But then @Sam_Holzmann went full design boi on it for me.

The window switches are both being relocated to where the cup holder/slider thing normally is in the center console. And then a small cubby added. Mostly because it would be dumb to not have anything else there.

Actual computer design.

And the first print. Which took 44 hours.

As of now he is going to make some tweaks for the hopeful final print. I'm super hyped for this one off piece! I cannot thank Sam enough for this one, it will be so much nicer than anything I could have made out of an ABS sheet.

-

1 minute ago, patsbimmer1 said:

I like this every time it's updated

I do my best! Honestly alot of the reason I update even on the littlest things is for myself. When I built my civic over the 8 years I had it I barely updated the build thread I did have, which was so much work. And sometimes the little stuff is informational and might help someone else too!

-

-

Not a whole lot of progress this weekend but got something done that I've been meaning to do since I first built the car.

Before I scrapped the stock bumper and bumper supports I cut off the tow hook threads, finally got around to welding them to the bash bars.

Here's the front. I welded the threaded chunk into a piece of tube then to the bar. Worked out really well.

The rear was alot simpler since I had added the jack point last spring. Lined up perfect so all i had to do was burn the piece right to the bar.

little thing that wont be noticed really but it felt good to get it done. Both just need some paint and are complete.

I also made some "CAD" templates for the rear door panels once the cage is in. I wont be able to fit the stock panels with how we are doing the cage so I'll be cutting them out of the same ABS that I made the bulkhead out of and then using nutzerts and some nice hardware to secure them.

-

Update.

Revised the front cage box design, measurements only so not much to show there.

Also revised and finished the rear cage boxes.

Then we cut, bent and did ALOT of trimming to get the rear boxes to fit as snug as possible.

Still might need a little more trimming but pretty happy with it.

The cage will most likely be mig welded just because we dont have the torch time to do tig. I have never learned to tig, and I'm ok at mig.

Moved on to starting to clean up the body work from the dent being pulled.

Layed down some filler.

And then sanded.

ALOT more detailed filler work and sanding is ahead but it's a start!

-

8 hours ago, Jdesign said:

I was going to say "Cardboard Aided Design"

Yes that's why I put it in quotes lmao. I've always called it cardboard aided design too

A purists nightmare - E46 drift build

in Members BMWs

Posted

UPDATE

Began the weekend by getting the quarters undercoated.

Then I got to work figuring out my new hand brake set up.

For starters this was NOT working out how I planned... but I did figure it out after ALOT of staring at the center council area and moving things around.

I am happy with the final result so far, it did take some "adjustment " of a spot welded bracket under the heater core though lol.

Here is the plate I cut out with the handbrake mounting plate.

And here it is primed and installed with the hanbrake bolted in as well.

Really liking how the location worked out. It feels comfortable and my arm doesn't hit the armrest either which I was concerned about originally.

I then mounted the resiviour which is now remote mounted rather than attached to the master.

I routed all the lines and just need to pick up some DOT5 fluid and get it bled.

So then I moved on to fitting the lower dash pocket thing near the handbrake. It worked out soooo well. Just trimmed out the 12v outlet and the result is below!

Still able to keep the ash tray which is cool too, not because I smoke but because its nice to keep smaller random stuff in there and not have it flying all over.

Just need to find a new shifter bezel and trim the top left corner and things should be looking really complete.

Finally I fitted the rear overs, all they need now is some wrap and final install.

Left side.

Here is the over mounted also with a 25mm spacer for now

And the right side.

Things are moving along nicely. Alot of things to address still but nothing super huge.

Also I did test fit the sunroof delete and it fits great, just need to get some new bolts.

Hopefully the windshield will be installed this week as well.

But thats it for this weekend!