-

Posts

149 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by ThatRatRodProject

-

-

On 12/28/2019 at 5:00 PM, Drgt5683 said:

Where you located ?? I can set this up for pick up exc , need my number to call me lmk?

I am Very interested the diff if you pick this up.

-

On 12/23/2019 at 9:45 AM, Nick_F said:

This is tempting... do you have the front bumper?

I sadly don’t. I had a m3 replica bumper on it but It ended up cracking and then I hit a cone auto crossing. Sorry with the holidays. I haven’t had a chance to respond.

-

-

-

For sale is a 2001 bmw 330xi with a welded center diff. I have all the components other then the front axle to reverse. Including an additional center diff. Used to be my daily. Since then I have been auto-crossing the car. Sitting on offbrand coil overs. And aftermarket wheels. Comes with a set of snow tires mounted on oem wheels nearly brand new. Runs perfect. No check engine lights. If it doesn’t sells I will continue to autocross the car in spring. 196,xxx miles. Asking 1600 obo.

-

-

19 hours ago, HipMF said:

Buy it and part it out? You'll get the diff for free and probably make some money on top of that as well.

Very tempting. I just need room for it. I have a full shop. Might have to try and sell a car.

-

If you ever turn this Into a part out. I will buy the diff in a heart beat.

-

-

Today’s progress flipped the frame back over and set the body back on. Dropped the motor in and line up the drive line components.

Up next motor mounts and rear sub frame modification. I have to finish weld the the front subframe. And waiting on rear wheel from bassets racing. So I can start string lining gauging for. Rear sub Frame mounts.

-

Pulled the frame out from underneath the car and worked on getting the front end mounted to the frame. Holiday week is letting me get some shop time in. I’m just waiting on the rear wheels From basset racing. and then I will have everything to make it a roller. Glad to see all me card board templates and napkin drawings are working out.

-

-

I’ve ran a few autocross events with my old daily last year and a couple this year. I need to get some tires for my car. Any one have any experience with any brands. Just got done with a full weekend of racing.

Friday night: Jefferson time attack 2nd place in the 6 cylinders class. And 5th overallSaturday: Drag racing at GLD with my buddy’s k swaped mr2

and Sunday Road America. Motoplex Autocross

Placed 4th in Stx

-

-

Just now, B C said:

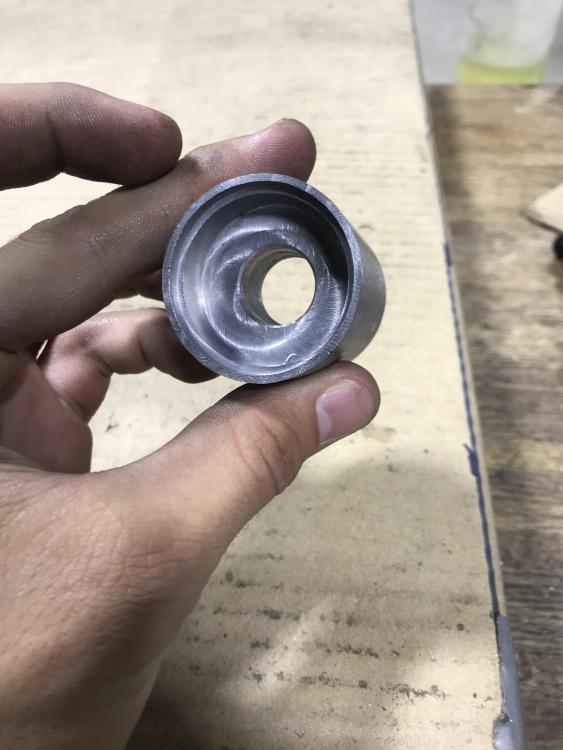

Great work man! You may also consider using oil impregnated solid thrust washers instead of roller bearing thrust washers if the loads are low enough and you want to improve environmental protection.

The castle nut is a great idea

I would like to possible try 3d Printing some bushings for weather protection. Out of some soft filament. Or Nylon

-

On 9/30/2019 at 4:49 PM, RobZR said:

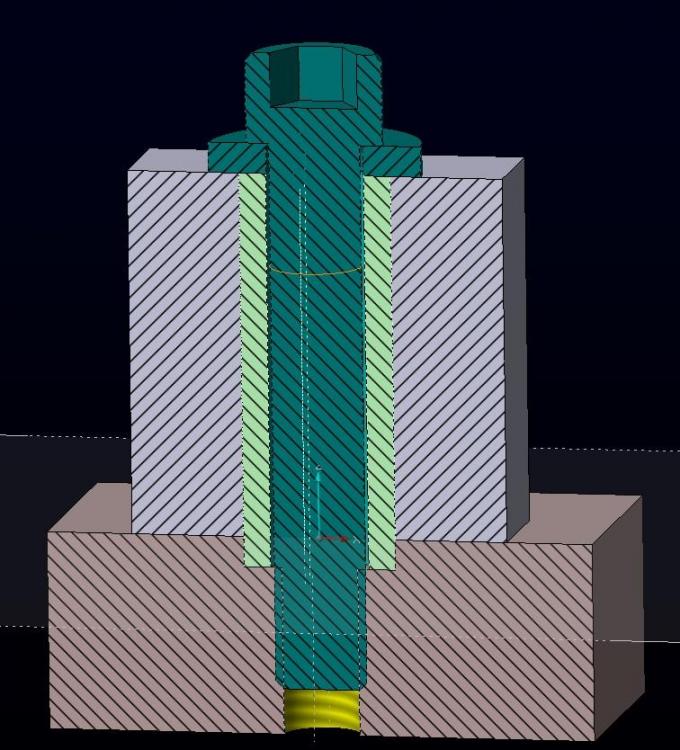

With some help from RobZR. I believe we have reached a much safer option from using a shoulder bolt. I made up this spindle design last night. This will have a castle nut and cotter pin in its end form. I did tighten it all down and I’m very pleased with how it turned out. zero play.

-

-

-

-

8 minutes ago, Jdesign said:

CAD to Metal overnight. I like your fast pace.

What did you use to cut the parts? Waterjet?

I work In a Tool Shop so i May have utilized Our CNC Laser.

I did have some of this work done Prior to posting the cad up date.

Its been after hours progress the past 2 weeks . I have 3 of the 4 Control Arms done. So you should see up-dates later this week.

-

25 minutes ago, RobZR said:

I would not recommend using a stripper bolt in this manner. They are not intended to handle lateral forces and have a inherent stress riser at the base of the thread that is prone to failure.

Ideally you would support both sides of the pivot point from the subframe. if you must support it from one side a spool and bolt design will bend before failure, since it keeps the bolt in tension.

I 100% agree with you. If you are using a Harden alloy shoulder bolt. But with that being said I will be mostly turning up a custom shoulder bolt . But any side load should be transferred to linear load with the thrust bearings. Not 100% transferred but lessened a great deal. I’m not saying you wrong in anyway and I will take any input I can.

-

-

-

42 minutes ago, GunMetalGrey said:

Yeah this project was always intriguing, but has certainly caught more of my interest seeing things being modeled!

The shear area on that upper shock mount seems reasonable if you've got good penetration welds on both plates.

I think I saw the knuckles in a picture on a previous page, but are those a standard purchased component?

I've always thought it would be cool to do a ground up build like this, so I really look forward to the continuation of this!The Knuckle is a ford Pinto Spindle. Primarily Used in circle track applications.

1993 e34 M5 *junk shell* with full drivetrain

in Cars For Sale & Wanted

Posted

Yes Still Interested in the diff.