cpandrewschmidt

-

Posts

202 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by cpandrewschmidt

-

-

Hi all. I recently replaced my front upper strut mounts on the e30. I seem to have worse vibration after the install than before.

Are they directional in any way? I thought they could only go in one way with the way the bolts line up to the holes, but I guess I'm not positive. I noticed the notch out of the metal but didn't pay attention to its direction when I pulled the old ones.

Thanks for the help -

which body shop has that paint? Which one is best match for BMW?

-

Got the nut off no problem with impact wrench. Got to buy a new one

I finally got this putting it back in last night. This job sucked. Part of the bearings froze onto the hub, had to cut and hammer and wedge in a vice to get it off. 2 hours alone messing with that. Bushings were all ok to put back in. Press was a life saver. No idea how anyone could do this without one. Some pictures of the carnage along the way. Saw online people burning their bushings out. That proved to be pointless because you still had to press out the metal sleeve. But I'm sure my neighbors appreciated the fire. Smashed my hand with a hammer and have taken more showers to get grease off in a week than I would normally in a month. Picture doesn't do justice to how dirty I really was! New GC Coilovers arrive today. Will get the rears in and button everything back up. Will get to the fronts in the next week or two. I have to cut 2" of the sleeve and reweld for the type of shocks I got. Gotta find a welder. I'll post more pictures when all done!

I finally got this putting it back in last night. This job sucked. Part of the bearings froze onto the hub, had to cut and hammer and wedge in a vice to get it off. 2 hours alone messing with that. Bushings were all ok to put back in. Press was a life saver. No idea how anyone could do this without one. Some pictures of the carnage along the way. Saw online people burning their bushings out. That proved to be pointless because you still had to press out the metal sleeve. But I'm sure my neighbors appreciated the fire. Smashed my hand with a hammer and have taken more showers to get grease off in a week than I would normally in a month. Picture doesn't do justice to how dirty I really was! New GC Coilovers arrive today. Will get the rears in and button everything back up. Will get to the fronts in the next week or two. I have to cut 2" of the sleeve and reweld for the type of shocks I got. Gotta find a welder. I'll post more pictures when all done!

-

-

thanks, yep i'll try my impact! Do e30 trailing arm bushings need to be preloaded? Any tips on doing that off the car?

-

working on the convertible. Subframe out, thanks for the tips @Jdesign . It dropped down just fine with out the bar trick. Guess I got lucky but this job still sucks btw! Had issues getting it to clear the driveshaft. Ended up having to undo the back half of that to get it to clear and drop. Have some nice smashed fingers.

I'm doing all my bushing while it's out. Ordered new Ground Control System Coilovers as well since my JOM's sucked.

Also doing wheel bearings. I forgot to losen my axel nut while it was on the car. Am I going to be screwed trying to get that loosened? Wonder if that will have to wait till things are buttoned back up?

-

-

-

i don't really have any noticeable knock or miss that I can hear. Pulls strong under under full throttle. I'll monitor again when I get it back out. Still curious to know more about if the injectors can be tuned or not. My DME says its: MS41.1 if that matters.

-

I have a datalog from a couple months ago saved in excel. Can't drive the car the next few days because of the snow. Jinxed us with putting summers on, sorry........

I tried to attach it here, not sure if it will work. In looking at the IGN category it starts out around the 15 mark and hovers there for a while, then goes up to the 30 ranges and hovers around there. I noticed at lines 8781, 9195, 9641, and 11785 it starts to drop down to 1 along with my Lamba sensors zeroing out. Could be something, could be nothing. I'm not really sure.

Again, this log was from a little bit ago. I assume if I do a few more runs it would overall look similar. I'll do that when I can drive again with the weather. If you all can take a peak at this and let me know your thoughts that'd be great.

-

I'm using an "autolink" scanner from a friend, same one on page 2 of this. There's a section for freeze frame data. It shows: DTCFRZF, FUELSYS1, FUELSYS2, LOAD_PCT(%), ECT(degreeF), SHRTFT1(%), LONGFT1(%), SHRTFT2(%), LONGFT2(%), RPM, VSS(mph) - what should I look for in that? Live data seems to show more categories.

I also have the ability to datalog from http://bimmersoftware.com/bmwlogger it shows pretty much same stuff as the live data along with Vanos IN/OUT

Hopefully that Admin gets back to you

-

Haven't swapped DME at all. Don't have an extra, or a car to swap into. Are there other ways to test DME? When you say ECU, it's the same as the DME, right?

For Injectors all I know about them if from when I sent them in. He said "They are "weber style" After cleaning The dynamic flow test ( 12 ms pulse width / 2400 rpm / 25 seconds ) had flow rates of 100 up to 104 cc.s across the board. The injector flow balance is now very close to 3.8 %. He said they all performed flawless in all the tests and All of the injectors held pressures over 80 psi without leaking a drop, and their spray patterns were perfect."

I'll pull one soon to get the model # off them.

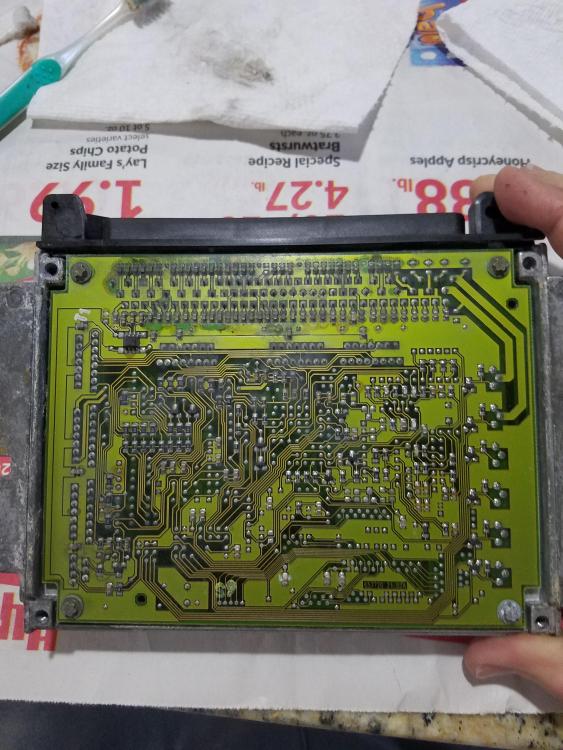

On my DME. I pulled it a few weeks ago to look at it. I've read about corrosion issues. Sure enough, it was pretty corroded. I thought that would be it. Attached are before and after cleaning pictures, along with the "chip" side, which was clean. I cleaned it real well with electrical cleaner. No difference in how car performed and it did clean up well. I would guess it was still OK, nothing looked fried on the chip side of things. No visible burn through marks on the board. Also, all live data systems like o2, stft, ltft, MAF etc all get readings when plugging in my code reader. So, they appear to be reading fine.

-

tried to check for exhaust leaks around manifold / before 02 sensors. Nothing that I could find. Couldn't get Coolant Temp sensor installed without removing supercharger. Highly doubt it's that anyway.

So, really thinking this thing it just putting too much fuel into it since I can't think of anything else to check. Everything else is solid, no leaks etc. Guess that brings me back to what you all might know about tuning injectors? I'm not 100% sure what ones i have. They have a blue O ring on them. Guess I'll have to pull one to confirm.

If there's anyone that can help with computer stuff that's where my knowledge stops. Willing to pay for help!

Andrew

-

Never not had a CEL. but i didn't know enough back then to look at fuel trim ratios. was focused on vacuum leak stuff as that is what everyone always talks about. Since I bought from out of state I assume previous owner cleared codes before selling. 1st thing I noticed were 02 sensors were actually disintegrated post CAT. did those 1st but still didn't fix CEL. Then did valve cover as that was leaking oil. Then the rest of the list above as other preventative maintenance along the way. Still haven't pin pointed it. Ordered up a coolant temp sensor for the block as they are only $25 bucks. Figured why not. Will try to put that in tomorrow too, but supercharger might make that a difficult job.

-

Morning all, time to pick your brains again. So, I've never been able to figure out my CEL issue and I'm determined. If you'd read back you'd notice car seems to run fine but I'm running rich. Quick summary: I get mixture deviation codes on banks 1 and 2 with negative fuel trims. I'll clear codes and monitor the live data. LTFT starts at zero then works its way to the -8.6% threshold fairly quickly where DME overrides and trips the CEL. I've noticed bank 1 gets there about -1% more quickly than bank 2, but then they both eventually get to the -8.6% I understand this to mean I don't have a vacuum leak as that would cause lean fuel trims (positive) Plus I've tested numerous times with smoke for any intake leaks.

Things I've done within the last 3-8,000 miles: valve cover gasket, vanos seals, fixed intake boot leak, fuel filter, new FPR, all new O2 sensors, sent out injectors for testing (tested good, no leaks), spark plugs, boots, coil packs. Unplug MAF and confirm idle change, so appears to be working. Cam shaft position sensor. The latest was the cam shaft position sensor. Old one was definitely compromised. It had frayed exposed wires. Light stayed off for 2 weeks and a lot of driving so I thought I found it. Then, came back. Same codes.

This brings me to a couple ideas.

1. Possible exhaust leak - I've read if the leak is on the exhaust side before the o2 sensors that can cause rich conditions. I'll be confirming tomorrow if there's a leak at the manifold or elsewhere. Assuming that's ok onto my next ideas.

2. When I got the car it was needing maintenance, valve cover leaked, intake, etc. My thought is perhaps the tune was done with these leaks causing causing misleading lean conditions. Now that I've patched them up, cleaned up fuel filter, fpr, etc it's just flowing that much better and running rich. My question is does anyone here know if you can tune injectors to not run as much fuel? Anyone here know how to for some $?

3. DME compromised? There's a guy on bimmerforums that'll re-flash the tune onto a new DME but that's $380 and i don't want to spend that if it's fine. Car doesn't experience any other symptoms so I assume it's OK?

4. Timing issue from vanos job. I've done it now 3 times checking my work and using the compressed air to confirm movement. Seems OK. But with bank 1 showing signs first maybe intake CAM is still off? Are there computers out there that can sense that? I did job using blocks and all lines up.

5. Coolant temp sensor?

I'm basically out of mechanical ideas to fix / test. Only thing I haven't changed is the CCV. I don't think that would cause a rich condition. I've cleaned out ICV. I was OK replacing all the other parts because they were maintenance items anyway, but now I'm out of things to fix.

Looking forward to hearing all your thoughts and wisdom! Willing to pay money for help. I just don't want to take to the deal because they'll do all the same things I've already done, unless their programs are more capable than what I have.

Thanks, Andrew

PS - detailed and put summer tires on, so you all can blame me if we get 6" of snow Friday night.

-

-

3 hours ago, m42b32 said:

Another option that I would guess would work, is to determine just how far you are lowered from stock in the rear. That number is easy to find if you have lowering springs as it should be a published value, less so if you have adjustable suspension. If you've got coilovers, there are published values from BMW for stock ride height from the ground to the wheel arch (or something like that) that you can compare to. If I'm thinking correctly, measure down from the center of the hub by the amount you are lower from stock ,and then up 8mm from that point to set the preload relative to your ride height.

As far as the vibration, unless your alignment is really out of whack, it is most likely that the new RTAB is 'uncovering' and issue elsewhere by transmitting vibrations that were previously being absorbed by the worn bushing.

note to my idiot self. it usually helps with vibrations to actually tighten lug nuts.............

rtabs all better now.

-

yes, stock w/ limiters. i got some tips on bimmerforums:

"Don't fully tighten the bushings bolt.

Install RTAB bracket to car, install wheel, lower car to ground.

Drive the car back/forward 10ft or so so the suspension can settle.

With a marker (pref a paint marker) reach into the RTAB bracket area and draw a line across the bracket relative to the trailing arm.

Put the car back in the air, remove RTAB bracket and you should now be able to line the RTAB bracket to the line you just drew. Now tighten and torque the bushing bolt. Tada!" -

Hi all, quick question. I replaced my RTABs this weekend. After I got done I discovered some threads talking about preloading them. I understand the concept and why to do it. Now I just have to figure out the proper way with out the BMW tool. Only it says use a straight edge and measure 8mm above the center of your hub. My questions are:

1. my car is lowered. Should i error slightly more than 8mm?

2. do you measure with the car fully jacked up? won't different cars with different suspensions sag more or less than others, throwing off that 8mm measurement?

3. do you measure for below or above the center of the hub?

I attached some pictures for reference of what I was doing. I was going to measure above center of hub, but still unsure of question #2. I think i tighten it too far off 8mm trying to account for my drop in suspension. I was getting a bad shake this AM from the one side i messed with. Will try to correct tonight.

Thanks for the help for anyone who's done this.

-

they all look same to me. I'll take pictures next time I have it out to show you. I'll be gone this weekend putting the vert into storage so won't have time to mess with it till Sunday.

-

Hi all, hope everyone is doing well. Not a ton to report on the M3. Got the new trunk on. Looks much better. Not 100% perfect unless you're very close to it and know what to look for. I like it. Small m5 spoiler coming today.

Back to the vanos stuff. Did it a 3rd time, confirmed chain movement was correct with compressed air. All seemed fine. Drove it for a couple weeks with no CEL. Had at least 30-40 different start and stops over the time period, so DME had plenty of time to trip early on but didn't. Then it came on again this week. Ugh, same thing, mixture deviation bank 1, misfire cylinder 5.

So, I did an experiment. I changed coil pack (CP) to cylinder 2 and spark plug (SP) to cylinder 3. Put known working CP and SP from cylinder 2 onto cylinder 5.

Now I get misfire on cylinder 5 and 3 (where the spark plug went) but cylinder 2 is good with the CP off 5. So, I know CP's are fine. (again all CP and SPs are new)

Something appears to be happening on cylinder 5 that messes up the spark plugs. I'm going to try to clear codes and reset DME adaptations, but leave everything where it is. I'll see if they come back as 3 and 5 misfires again. If so I'll move 5 spark plug to another location to see if that follows.

Maybe something with the wiring harness or could be computer related? Ugh.

Would love to get this sorted out. I don't have anyway to live monitor stuff while the engine is running to see if it is truly misfiring or look at other parameters. I think that's the next step.

-

I took my m20 head to Performance Engine and Machine in Middleton for all of the above you mentioned needing done. I think it was like $250 for everything. No idea if that was good or not as it was the only place around me I could find.

-

-

well, didn't make a difference with cam locks off. Same thing. I've taken the whole thing apart again and reinstalled. Same problem. Took the vanos apart to check seals and inside. Those all seem fine.

Perhaps my rig for applying air? Should I not have the oil feed line attach? I have an aftermarket oil pressure guage that tees off that, so mine is a bit different. I was able to get a hose clamp attached to that. Air doesn't leak and does go through even with the kink. Other end just connected to the compressor with 60 psi. I do hear air coming out from somewhere under the exhaust cam gear. I assume oil feeds into the head somewhere in there. But air pressure definitely escapes through there.

e36 M3 rear sway bar $50

in Parts For Sale

Posted

Have a rear sway bar for an e36 M3. Not sure if non M3s can upgrade to the thicker version or not. Needs mounting hardware but that's cheap online. $50 obo, located in Madison.