cpandrewschmidt

-

Posts

202 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by cpandrewschmidt

-

-

Hey all,So working on this right now tonight. I followed the steps above (cam locks, backed off torx bolts, tension on chain). I wanted to check chain movement before uninstalling vanos just to see where it was at. Applying pressure and activating the solenoid the chain didn't budge. You can hear the vanos make a blurping noise and the cylinder with the gear moves in and out just a little bit. Appears the solenoid is fine as it clearly does something when voltage is applied to it.

So, figured it was installed wrong, uninstalled and re-installed. Same thing. I'm very careful to make sure I'm catching the 1st possible gear.I'm surprised that 60 psi is going to move the chain. It's hard enough to move the chain clockwise with the cam gear wrench. Doesn't seem like anything will move with the CAM blocks on.

I took a video but not sure how to post a video. I'll try to figure that out. If anyone has any ideas in the meantime please let me know. -

4 minutes ago, Jdesign said:

I clicked on the website. They want $25 to register and "search" inventory. Wonder how legit it is?

-

Thanks Snap. That's pretty much the same response I got on the M3 forums. I'll let you all know how it goes.

"Locks on

E-torx loose

Chain tension yes

The idea is to set the position (air on, solenoid off) to lock the exhaust torx down. The same thing you did when attempting by hand. You also get to see the movement range while cycling on/off several times on the solenoid before finishing with off to tighten the torx. " -

I'm about to tackle this vanos yet again tonight. This time with compressed air. I'm seeing conflicting info online on the procedure though.

1. Do I keep the cam lock blocks on?

2. Loosen the exhaust torx bolts a bit?

3. Lastly, do you put tension back on the chain?If anyone knows for sure that'd be great! Thanks

-

well damn. Injector guy just called back after testing. Said they're 100% fine. Figured since they really only have about 27k miles on them.

Looks like I'll be trying my vanos job one more time. Really isn't anything else I can test at this point. Gotta track down that air tool to test chain movement that I'm reading about online. Can't find it anywhere.

-

-

2 hours ago, Snap said:

Did you use a dummy chain tensioner tool when you did your cam timing?

The fun part about my build is its OBD1 with no check engine light so if my engine runs funny then I don't get too many hints as to what it may be. Here is to hoping I fire mine up within the next month and it is perfect, and that yours is just some crummy injectors.

all i used for the tensioner tool was pressed down on the upper tensioner and then inserted a small nail into the hole to hold it down so the chain had slack. That's what the beisan instructions lead me to believe is all i had to do. http://www.beisansystems.com/procedures/vanos_single_procedure.htm

-

Yeah. I'll start there for piece of mind. Still think it could be my vanos job. I've been reading about more steps on that and some people swear by having to test is with air for correct chain movement before buttoning up. But, not too expensive to ship off the injectors so taking those off tonight. Using this guy. I've emailed with him. http://injectorrepair.com/flow-testing-process/

-

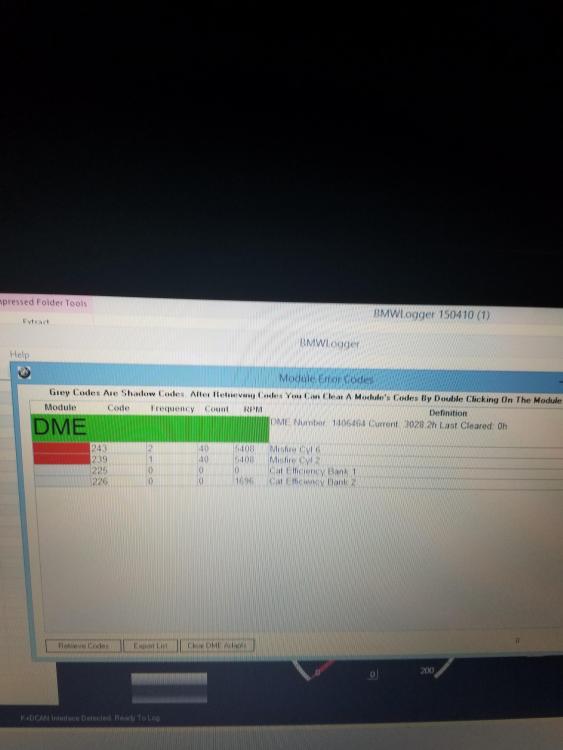

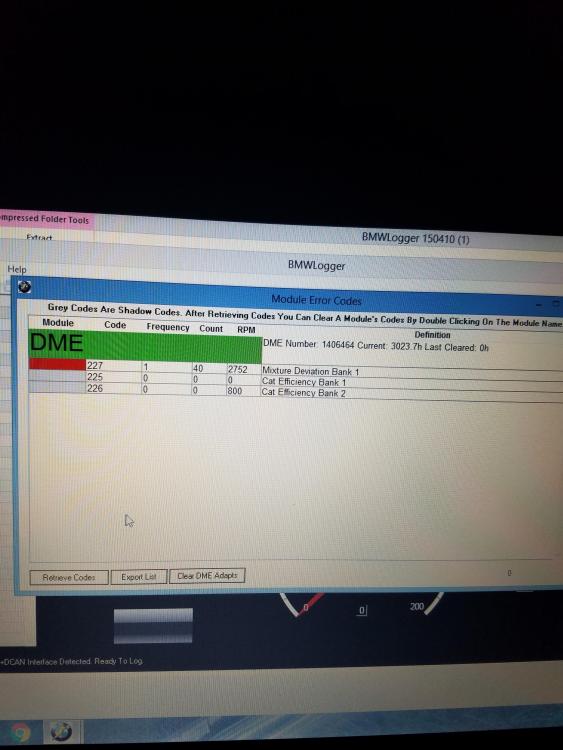

Cleared codes and reset DME this AM. Took to work today. Start up was rough again, smoothed out after normal driving. Although I feel even after warm up the sound of the exhaust is a little sputtery. Pulled the same misfire codes on 2 and 6 and cat efficiency codes. No mixture deviation yet, but that might come on with more driving I suspect.

-

thanks guys. Will do tonight and report back. I found it strange that cylinder 6 now had a misfire as well. I didn't check for a dripping injector unfortunately.

-

Just moved injectors. Plugs are also new. Looked fine when i pulled them for vanos job before. I didn't put them back in the same spots so the misfire staying on 5 wouldn't have been plug related. In the past i've moved those and coil packs. Code stayed on 5. So, plugs and packs should be good.

-

I had some time to noodle around with this over the weekend. Here are a few observations. Before moving injectors in addition to the codes above I would get a misfire on cylinder 5. Wouldn't happen all the time, but somewhat consistent. I've replaced all spark plugs and new coil packs but code persists.

So, I removed plugs and rotated them around. 1 to 4, 2 to 5, 3 to 6 and then 6 to 3, 5 to 2, 4 to 1.

New codes come up as: Misfire cylinder 2 and 6. (2 makes some sense since I moved 5 to that spot. 6 makes no sense) I have mixture deviation on Bank 2 now vs bank 1. Also, both Cat Efficiency Bank 1,2 still. After moving them and starting the car I could feel the misfires right away. However, after car warms up it appears to run perfectly fine.

Anyway to test injectors besides sending them in to get cleaned and tested? Seems weird for 6 to go bad. That would have been in slot 1 before and I've never had a code there. I wonder if there's something up with my electrical signal to them? I probably stretching here.

Appreciate any thoughts.

-

17 minutes ago, jc43089 said:

So when it was all put together with the vanos installed and after turning the engine a few times and back to TDC the squares on the cams are straight with each other and the cam locks can be put back on?

yes

-

Well, got things buttoned back up last night. Here are some steps I took. Loosened exhaust CAM bolts with crank at TDC. Pushed in upper timing chain tensioner with pin. I was able to rotate exhaust CAM with wrench to put in CAM block locks. Intake side CAM lock slid on with no adjustment needed. I did not remove any chains. Rotated CAM sprocket to right while removing vanos. Re-set vanos very carefully to insure tooth caught while rotating CAM sprocket back to left. Spline tooth caught right away. Removed tensioner pin and locks. Checked timing on TDC with several rotations. All looked good. Buttoned rest back up. Cleared codes and DME adapations.

Took car for a spin now have a new gremlin. Car idles normally while cold and during warm up. Once the car is warm when coming out of gear into neutral the rpms start to flutter. Will typically dip to around 300 rmp then spike to 900 and keeps going back and forth. Doesn't do it all the time but is pretty consistent. My normal idle was around 650 rpm or so. On first trip out dipped low enough to kill the engine. Basically getting the same codes, now with the idle issue which is new. Perhaps I still have something wrong with my install. Not sure where to go from here.

-

Hi all,

Couple months or so ago I did a Vanos reseal. I have a lightweight flywheel which doesn't have a pin to lock the flywheel. I made some CAM locks myself and proceeded with the job. During the job my locks slipped a bit. I realigned with the head as best I could and proceeded. When done verified TDC on flywheel and all looked good through several rotations.

Since then I've been battling those codes you've seen in this thread. I've replaced all known issues for that; plugs, coil packs, o2 sensors, fuel filter, smoke test, etc. I planned to do all those anyway as routine maintenance as the new owner so that's fine. However, I'm still getting the code. So, that brings me back to my Vanos job as the only other variable that's changed. More I read I see people talking about it being off a "tooth" Are they referring to the splines when re-inserting the Vanos? After watching some video's I'm not 100% confident I had that in correctly. So, I'm re-doing it to double check my work. After seeing a few techniques on youtube i'm more confident I'll be sure it's right.

I'm at the point to lock the CAMs (with real cam locks this time). Here's a picture of my exhaust cam. Crank is TDC, lobes pointed at each other upfront and intake cam is pretty flush. Exhaust is off by a bit. I'm told to wiggle the CAM with a 24 mm wrench so it sits flush but I'm afraid of other things moving. I plan to have a friend hold a wrench on the crank to insure that doesn't move, but am I ok to wiggle that CAM around? I didn't want to take the Vanos out without knowing that first.

Thanks for any advice for those that have done this.Andrew

-

-

clean looking e30 vert

https://masoncity.craigslist.org/cto/d/1992-bmw-318i/6297868677.html

tempting for a 5 speed swap

https://minneapolis.craigslist.org/hnp/cto/d/bmw-325i-1989-low-miles/6278846842.html

-

On 9/2/2017 at 0:42 AM, patsbimmer1 said:

Buy some hdpe from menards. You won't regret it! I agree with jdesign, carry it all the way across the front.

yeah, will definitely look at HDPE for it. I'm going for this look. I think carrying it all the way across just makes it look too much like the stock splitter already on there. But I'll still mock one up to see if I like it more.

-

-

yeah, my CAT is on there. Junk yard?!? You could always weld one in from a non-vert too i'd think.

-

There would be a CAT closer to the headers on the stock exhaust

http://www.realoem.com/bmw/enUS/showparts?id=BB13-USA-07-1991-E30-BMW-325i&diagId=18_0170

Here's what the rear section should look like

http://www.realoem.com/bmw/enUS/showparts?id=BB13-USA-07-1991-E30-BMW-325i&diagId=18_0171

Suppose we could have looked this up last night

Andrew

-

not much new going on for the M3. Finally got around to a much needed interior and engine detailing. Saw Gliptone recommended on some other sites for leather seats. This stuff is great. https://www.amazon.com/gp/product/B003VV423G/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 Cleaned and re-treated with it. Finally fixed the saggy glove box too. Now just need some real M3 floormats and zhp knob.

-

On 8/25/2017 at 1:39 PM, P_Roloff said:

I believe I saw @cpandrewschmidt westbound on the beltline in Madison this morning, black e30 vert?

Ha, yep that was me! I was wondering if you'd be on here

-

https://detroit.craigslist.org/wyn/cto/d/bmw-i/6232814058.html

somewhat cheaper e30 no mileage listed. needs better rims.

new to me, 98 M3

in Members BMWs

Posted

got a video on you tube. you can see the vanos gear thing twitch with I apply voltage to it on and off